Meeting convention and event organizers plan the entire event from transportation to accommodations. They also need to establish positive relationships with suppliers and clients. They also need to be aware of the latest trends and best practices in meeting management. This job can be extremely rewarding.

Event planners work for more than 40 hours per week. They must be able multitask and achieve multiple objectives. They organize entertainment and audio-visual displays. They need to think about the event's budget and create the right atmosphere. Often, they plan a meeting more than a year in advance. They need to be able communicate with many people and understand clients' needs.

Meeting, Convention and Event Planners often work in government agencies and professional associations. They may also work in convention centers, trade show services, or fundraising events. They must be able collaborate with others to ensure that all requirements are met. They must be able and willing to come up with creative solutions. They must also be able to meet tight deadlines. Their salaries are often very high. Based on their experience and whereabouts, event and meeting planners can earn up to $55,891 annually. The median salary in this field is $51,600.

People who wish to work as a planner for meetings, conventions or events may benefit from continuing education. They can also obtain certifications that prove their expertise in the field. These certifications are a way for them to stand out in an increasingly competitive job market. Some certifications require experience with planning meetings, such as the Society of Government Meeting Professionals certification. They also require applicants to pass a qualifying test.

Meeting, convention, and event planners are typically interested in the following interest areas: helping, persuading, organizing, and keeping things in order. They collaborate with sponsors and suppliers to create and execute plans. They may also organize speakers and other related activities. They may be skilled in fundraising for professional associations and government agencies. They will need to be able and able to negotiate service agreements and meet tight deadlines.

The job of a convention planner, meeting planner, or event planner may require a lot of experience. The US Department of Labor estimated that there are approximately 125.900 meeting planners. The number of job openings will increase over the next decade. However, many of these are likely to be due to the need to replace employees. In 2020, the number of jobs will grow by seven percent and by 2028 by 18 percent. The national wage distribution shows the salary for a meeting, convention or event planner. The salary for a senior meeting, convention, or event planner is $88,360 per year.

Many different job titles can be used to plan events, meetings, and conventions. International Association of Exhibitions and Events gives the Certified Events Manager (CEM), title. Additionally, the Events Industry Council manages the Certified Meeting Professional credential (CMP). These certifications could help someone stand out within the meeting and event planning business.

FAQ

Is automation necessary in manufacturing?

Not only is automation important for manufacturers, but it's also vital for service providers. It allows them provide faster and more efficient services. They can also reduce their costs by reducing human error and improving productivity.

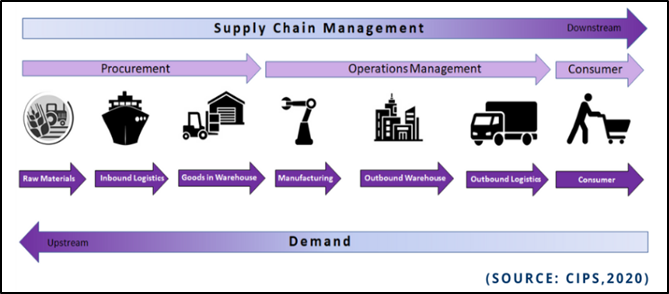

What are manufacturing & logistics?

Manufacturing is the production of goods using raw materials. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Manufacturing and logistics are often considered together as a broader term that encompasses both the process of creating products and delivering them to customers.

How can we improve manufacturing efficiency?

The first step is to identify the most important factors affecting production time. We must then find ways that we can improve these factors. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you identify them, look for solutions.

What kind of jobs are there in logistics?

There are many types of jobs in logistics. Some examples are:

-

Warehouse workers – They load and unload pallets and trucks.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers - They sort and pack freight in warehouses.

-

Inventory managers – They manage the inventory in warehouses.

-

Sales representatives - They sell products to customers.

-

Logistics coordinators - They plan and organize logistics operations.

-

Purchasing agents – They buy goods or services necessary to run a company.

-

Customer service representatives - They answer calls and emails from customers.

-

Shipping clerks – They process shipping orders, and issue bills.

-

Order fillers are people who fill orders based only on what was ordered.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others – There are many other types available in logistics. They include transport supervisors, cargo specialists and others.

How does a production planner differ from a project manager?

The major difference between a Production Planner and a Project Manager is that a Project Manager is often the person responsible for organizing and planning the entire project. While a Production Planner is involved mainly in the planning stage,

What skills should a production planner have?

To become a successful production planner, you need to be organized, flexible, and able to multitask. You must also be able to communicate effectively with clients and colleagues.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma refers to "the application and control of statistical processes (SPC) techniques in order to achieve continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. The basic idea behind Six Sigma is to improve quality by improving processes through standardization and eliminating defects. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. Six Sigma aims to reduce variation in the production's mean value. It is possible to measure the performance of your product against an average and find the percentage of time that it differs from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you've understood that, you'll want to identify sources of variation. Also, you will need to identify the sources of variation. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. Random variations would include, for example, the failure of some widgets to fall from the assembly line. However, if you notice that every time you assemble a widget, it always falls apart at exactly the same place, then that would be a systematic problem.

Once you identify the problem areas, it is time to create solutions. It might mean changing the way you do business or redesigning it entirely. To verify that the changes have worked, you need to test them again. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.