Journal impact factors

The Journal Impact Factors in Supply Chain Management are an effective tool for comparing the relative influence of supply-chain management journals. These factors are calculated by using data from ten leading academic supply chain management journals and the ISI Web of Science database. The results allow us to compare and contrast the relative influence of journals and their authors in the field.

Journal impact is an important indicator of quality. A high-ranking journal is more likely to have high quality research because it attracts top-quality work. Journal impact factors include the number of citations that a journal receives as well the importance of the journals. The publisher of the Journal is Emerald Group Publishing Ltd., a publishing company based in the United Kingdom.

Scope of this journal

Journal supply chain management's scope includes a range of topics such as inventory management and transportation. Its goal is to provide a dynamic forum for research-based knowledge on these areas. Articles on these topics are welcomed by the journal. The journal does not require that all submissions be published.

SCMij is an international publication that publishes research to advance the field of supply-chain management. It serves as a forum to discuss theoretical and empirical research. Scholars, practitioners, as well as students can submit articles to the journal.

Editorial Board

An editorial board is an independent body that assesses the quality and relevance of scientific publications. Its membership consists of renowned scientists from different fields of knowledge. The Board maintains confidentiality of manuscript information, and is bound to the editorial codes of conduct. The journal is available for search through major search engines and is listed in numerous international scientific databases.

The Journal of Supply Chain Management's Editorial Board is composed of experts in supply chain management, procurement and logistics. Every article submitted for publication goes through peer review to ensure that it's both relevant and useful.

Authors of articles that were published in the journal

Submissions to the Journal of Supply Chain Management are welcome from all supply chain, logistics, procurement professionals. The journal publishes original research as well as review articles on the subject of supply chain management. The articles should not exceed three thousand words and must discuss new techniques or solutions to problems.

Articles may be submitted online. They can be submitted in text format or as separate files with illustrations. Authors must ensure that their contact information is correct. The article should include the most current address and email. The journal is free to publish or submit.

Each year, number of articles published in this journal

The Journal of Supply Chain Management publishes articles across several journals. The journal's h index is high, which means that it is high in productivity and has high citation impacts. The total ISSN for the journal is 15232409, which corresponds to the International Standard Serial Number.

This journal publishes articles from academics and practitioners working in the field of supply chain management. Its articles offer thought leadership in supply chain operations. It also publishes columns and features by supply chain practitioners as well as industry analysts. It also publishes case stories of companies as well as their supply chains.

FAQ

What are the four types of manufacturing?

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. Manufacturing can include many activities such as designing and building, testing, packaging shipping, selling, servicing, and other related activities.

What does manufacturing industry mean?

Manufacturing Industries are businesses that produce products for sale. These products are sold to consumers. These companies use various processes such as production, distribution, retailing, management, etc., to fulfill this purpose. They make goods from raw materials with machines and other equipment. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

Is there anything we should know about Manufacturing Processes prior to learning about Logistics.

No. No. But, being familiar with manufacturing processes will give you a better understanding about how logistics works.

What are the main products of logistics?

Logistics refers to all activities that involve moving goods from A to B.

They include all aspects of transport, including packaging, loading, transporting, unloading, storing, warehousing, inventory management, customer service, distribution, returns, and recycling.

Logisticians ensure that the right product reaches the right place at the right time and under safe conditions. Logisticians help companies improve their supply chain efficiency by providing information about demand forecasts and stock levels, production schedules, as well as availability of raw materials.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to Use lean manufacturing in the Production of Goods

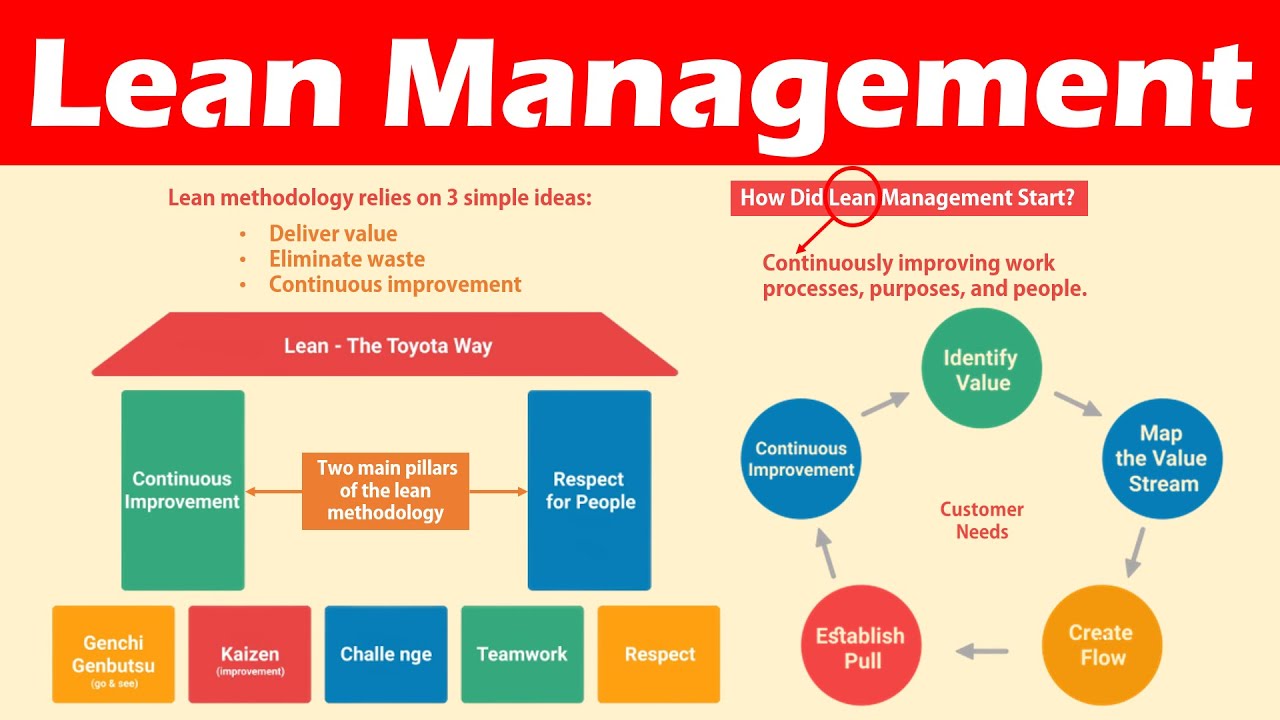

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was first developed in Japan in the 1970s/80s by Taiichi Ahno, who was awarded the Toyota Production System (TPS), award from KanjiToyoda, the founder of TPS. Michael L. Watkins published the "The Machine That Changed the World", the first book about lean manufacturing. It was published in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes reducing defects and eliminating waste throughout the value chain. Just-in-time (JIT), zero defect (TPM), and 5S are all examples of lean manufacturing. Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Lean manufacturing is widely used in many industries. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Lean manufacturing is based on five principles:

-

Define Value - Identify the value your business adds to society and what makes you different from competitors.

-

Reduce waste - Get rid of any activity that does not add value to the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. To increase their competitiveness, many businesses have turned to lean manufacturing. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

It can be applied to any aspect of an organisation. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three main types:

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT means that components are assembled at the time of use and not manufactured in advance. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.