The job description for an industrial engineer includes the science and art of time-and motion. This engineer examines the interaction of people with machines, systems and energy. Industrial engineers also need to have an understanding of economics as well as mechanical engineering. A basic understanding of algorithms is required. There are many requirements for industrial engineering, and each employer will have a different job description. You can apply for an engineering job if you hold a bachelor's degree.

Work environment

Among the many essential qualities for an industrial engineer are analytical thinking and high interpersonal skills. In an industrial setting, they use the skills that they have acquired in their previous jobs. Industrial engineers lead moderately complex industrial engineering projects and complete statistical analyses to improve standard times and production flow. They can also manage strategy execution by conducting Value Stream Mapping, Bottleneck Analysis and Value Stream Mapping. They may work in multidisciplinary teams to address multiple problems simultaneously.

Education

Relevant work experience will increase your chances to land a job in the industrial engineering field. Some degree programs require that interns gain practical experience. However, some employers will hire you even after graduating. Industrial engineers can also be specialized certified. Professional certifications not only prove that you possess required skills, but they also show that you're committed to ongoing professional development. Here are some great ways to start your search for an industrial engineering position.

Salary

The average salary for an industrial engineer job is $81,700 per year in the United States. This job's salary depends on experience and education, as well the market, industry size and market. Industrial engineers also have responsibilities in the area of Packaging Engineering. This position requires long hours of standing, and may also involve other duties like working with a team to develop new products. The ability to analyze and communicate data is essential for industrial engineers.

Certificates

An industrial engineer certification can help you improve your job performance. A lot of industrial engineer certifications require extensive study, courses, and exams. These certifications have many benefits for employers and are easy to obtain. Industrial engineers used to need to travel to other colleges or institutions to get the certifications they needed. Online training makes it faster and more convenient to obtain the certification.

Myers Briggs personalities type

Your Myers Briggs personality type will help you to find the job you want if you are aspired to be an engineer. This test, also known as the MBTI, measures four types: Introverted-Intuitive-Thinking, Sensing/Intuitive, Thinking/Feeling, and Perceived/Judged. It's a useful tool for both employers and employees.

FAQ

Is automation important for manufacturing?

Automation is important not only for manufacturers but also for service providers. It enables them to provide services faster and more efficiently. In addition, it helps them reduce costs by reducing human errors and improving productivity.

Do we need to know about Manufacturing Processes before learning about Logistics?

No. No. However, knowing about manufacturing processes will definitely give you a better understanding of how logistics works.

What is production planning?

Production Planning is the creation of a plan to cover all aspects, such as scheduling, budgeting. Location, crew, equipment, props and other details. This document will ensure everything is in order and ready to go when you need it. You should also have information to ensure the best possible results on set. It should include information about shooting locations, casting lists, crew details, equipment requirements, and shooting schedules.

It is important to first outline the type of film you would like to make. You may have already chosen the location you want, or there are locations or sets you prefer. Once you have identified your locations and scenes it's time to begin figuring out what elements you will need for each one. You might decide you need a car, but not sure what make or model. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

After you have selected the car you want, you can begin to think about additional features. Do you need people sitting in the front seats? You might also need someone to help you get around the back. You may want to change the interior's color from black or white. These questions will help to determine the style and feel of your car. You can also think about the type of shots you want to get. You will be filming close-ups and wide angles. Maybe you want to show the engine and the steering wheel. These things will help you to identify the car that you are looking for.

Once you have made all the necessary decisions, you can start to create a schedule. You will know when you should start and when you should finish shooting. Every day will have a time for you to arrive at the location, leave when you are leaving and return home when you are done. It will help everyone know exactly what they have to do and when. You can also make sure to book extra staff in advance if you have to hire them. There is no point in hiring someone who won't turn up because you didn't let him know.

When creating your schedule, you will also need to consider the number of days you need to film. Some projects are quick and easy, while others take weeks. It is important to consider whether you require more than one photo per day when you create your schedule. Multiplying takes in the same area will result both in increased costs and a longer time. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Another important aspect of production planning is setting budgets. A realistic budget will help you work within your means. Remember that you can always reduce the budget later on if you run into unforeseen problems. It is important to not overestimate how much you will spend. You'll end up with less money after paying for other things if the cost is underestimated.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

Why automate your warehouse?

Modern warehousing has seen automation take center stage. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses must adapt quickly to meet changing customer needs. To do so, they must invest heavily in technology. Automating warehouses has many benefits. These are just a few reasons to invest in automation.

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety increases

-

Eliminates bottlenecks

-

Companies can scale more easily

-

This makes workers more productive

-

This gives you visibility into what happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

Quality products delivered on time

-

Eliminates human error

-

It ensures compliance with regulations

Why is logistics important in manufacturing?

Logistics are an essential component of any business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics are also important in reducing costs and improving efficiency.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

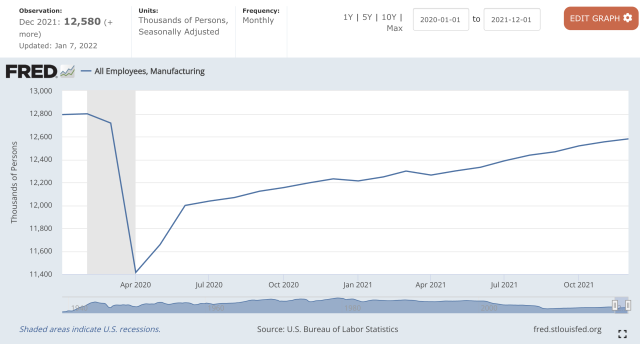

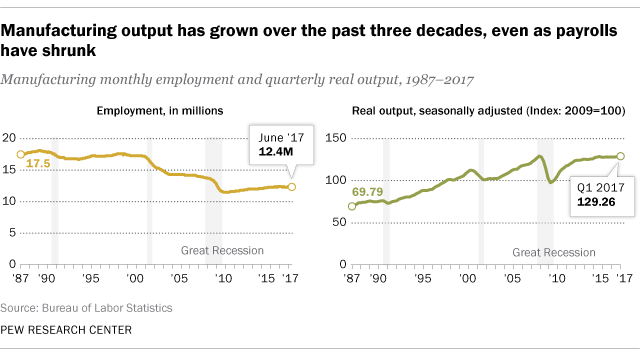

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

Six Sigma in Manufacturing:

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." Motorola's Quality Improvement Department, Tokyo, Japan, developed it in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. The main goal of Six Sigma is to reduce variation from the mean value of production. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If there is a significant deviation from the norm, you will know that something needs to change.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you understand that, it is time to identify the sources of variation. Also, you will need to identify the sources of variation. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. For example, if you're making widgets, and some of them fall off the assembly line, those would be considered random variations. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

Once you have identified the problem, you can design solutions. That solution might involve changing the way you do things or redesigning the process altogether. You should then test the changes again after they have been implemented. If they don't work, you will need to go back to the drawing boards and create a new plan.