One-piece flow production can increase your output while reducing inventory and lead times. There are a few things to consider before implementing this technology. You'll need to measure the takt-time, which is the amount of time it takes to create an item. This allows you to calculate how quickly you need to produce an item to meet the demand of your customers.

For low-variability products, one piece flow is the best choice. It is not the right fit for all businesses. It is important to ensure that you measure the right metrics in order to determine if this type process is right to your company.

The use of a single-piece flow will require a more robust, scalable control mechanism. This will minimize waste and maximize efficiency. You should also ensure that the time needed to produce a single-piece item is sufficient to meet the requirements of your customers. This will ensure that one-piece production doesn't suffer from the same efficiency as traditional production.

One piece flow is achieved by using a production process that looks like an U or S. Because it reduces movement between steps, this is important. It also allows for greater assembly efficiency.

The poka-yoke refers to a clever way of preventing defects from getting to the next step. This is a great method to save time, money, and increase the quality of your product. Poka-yoke can also reduce waste and inefficiency.

When there is high demand for individual products, the one-piece flow method works well. If you are looking to save money and time, it is a good idea to batch together items from the same order. One work item flow will decrease the delay cost and depreciation of inventory. It will also reduce how long your products remain in the warehouse, or work in process (WIP).

One-piece flow can also be used to reduce your inventory costs. This is especially true of small businesses. This type of process allows you to reduce the amount of money you have to spend on inventory storage, transporting, and re-packaging your products. This is a great way for you to cut down on the time that it takes to get your products to your customers.

By allowing employees and managers to work together, the one-piece process helps boost employee morale. It also makes it much easier to identify issues with your product. This is important as it could mean that your customers may receive defective or incomplete goods. This is another great way to improve your customer care.

You can use a one-piece production line inside and outside an assembly plant. This type of process is ideal for optimizing your value stream. This allows for quicker production and better quality products. It can also be a great way of reducing costs and boosting morale among employees.

FAQ

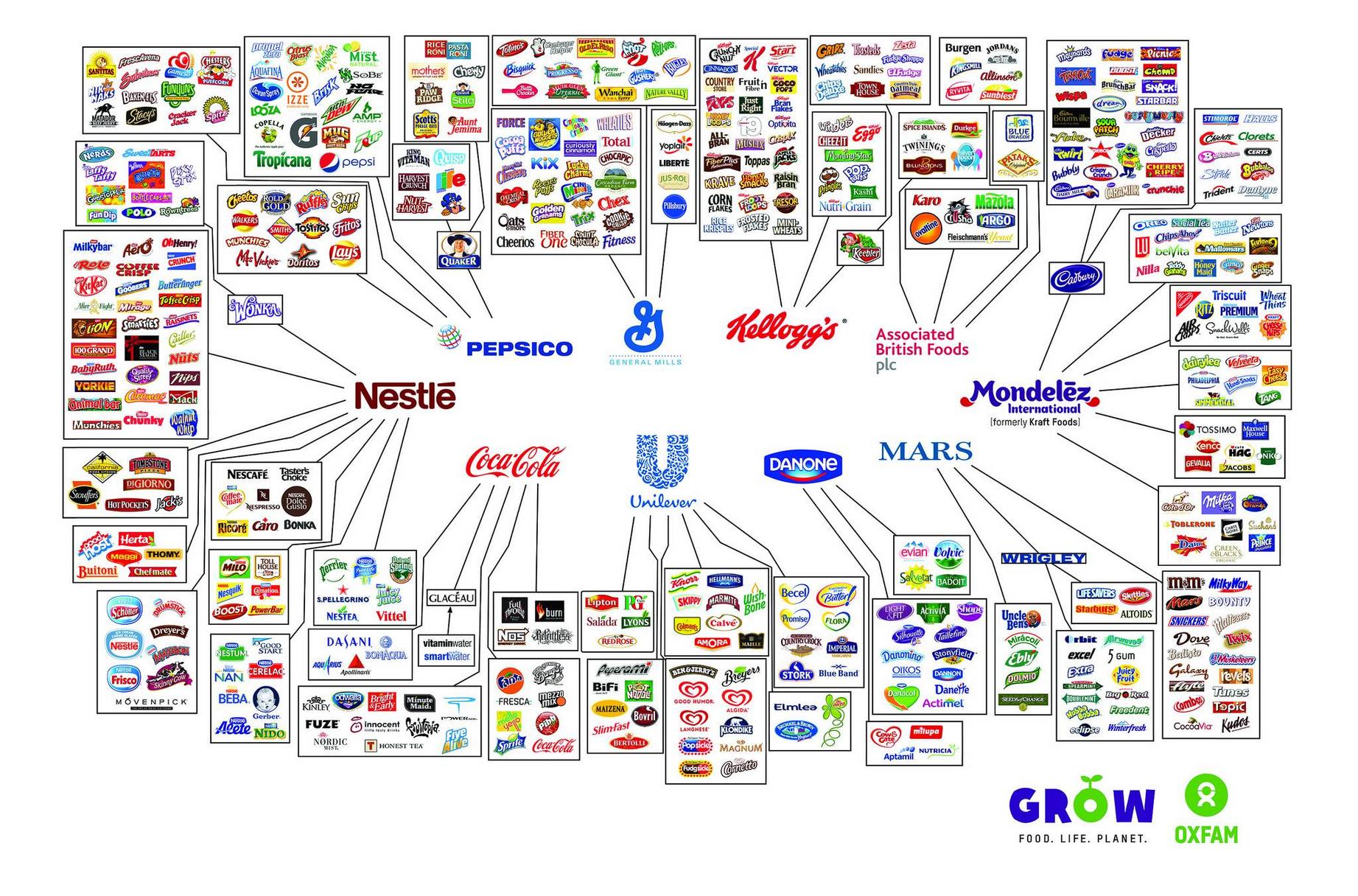

What is meant by manufacturing industries?

Manufacturing Industries is a group of businesses that produce goods for sale. Consumers are those who purchase these products. These companies use a variety processes such as distribution, retailing and management to accomplish their purpose. They manufacture goods from raw materials using machines and other equipment. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

What types of jobs can you find in logistics

There are many jobs available in logistics. Here are some:

-

Warehouse workers – They load, unload and transport pallets and trucks.

-

Transportation drivers - They drive trucks and trailers to deliver goods and carry out pick-ups.

-

Freight handlers are people who sort and pack freight into warehouses.

-

Inventory managers – These people oversee inventory at warehouses.

-

Sales representatives - They sell products to customers.

-

Logistics coordinators – They plan and coordinate logistics operations.

-

Purchasing agents are those who purchase goods and services for the company.

-

Customer service representatives are available to answer customer calls and emails.

-

Shipping clerks - They process shipping orders and issue bills.

-

Order fillers – They fill orders based upon what was ordered and shipped.

-

Quality control inspectors: They inspect outgoing and incoming products for any defects.

-

Others - There are many other types of jobs available in logistics, such as transportation supervisors, cargo specialists, etc.

What is the difference between manufacturing and logistics

Manufacturing is the act of producing goods from raw materials using machines and processes. Logistics encompasses the management of all aspects associated with supply chain activities such as procurement, production planning, distribution and inventory control. It also includes customer service. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

What does it take for a logistics enterprise to succeed?

It takes a lot of skills and knowledge to run a successful logistics business. You must have good communication skills to interact effectively with your clients and suppliers. You need to understand how to analyze data and draw conclusions from it. You must be able manage stress and pressure under pressure. You must be creative and innovative to develop new ideas to improve efficiency. You must be a strong leader to motivate others and direct them to achieve organizational goals.

It is important to be organized and efficient in order to meet tight deadlines.

What are the responsibilities of a manufacturing manager

A manufacturing manager has to ensure that all manufacturing processes work efficiently and effectively. They should also be aware of any problems within the company and act accordingly.

They should also be able communicate with other departments, such as sales or marketing.

They must also keep up-to-date with the latest trends in their field and be able use this information to improve productivity and efficiency.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to use Lean Manufacturing in the production of goods

Lean manufacturing is an approach to management that aims for efficiency and waste reduction. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes the elimination of defects and waste throughout the value stream. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing is considered one of the most effective ways to manage the entire value chain, including suppliers, customers, distributors, retailers, and employees. Lean manufacturing is widely practiced in many industries around the world. For example, Toyota's philosophy underpins its success in automobiles, electronics, appliances, healthcare, chemical engineering, aerospace, paper, food, etc.

Five fundamental principles underlie lean manufacturing.

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many companies have adopted lean manufacturing methods to increase their marketability. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing has many benefits in the automotive sector. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

You can apply Lean Manufacturing to virtually any aspect of your organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three main types of lean manufacturing:

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous improvement refers to continuous improvement of processes as well people and tools.