Facilities engineers (also known as maintenance engineers) are professionals who provide support in engineering and construction for buildings and operations. You will find their tasks include planning and implementing procedures, making recommendations for repairs and upgrades, and organizing routine and emergency maintenance. A wide range of engineering disciplines can play a part in their role, including electrical, mechanical, and plumbing. They are skilled in technical knowledge, but also have an excellent understanding of the law and safety standards that govern construction.

Facilities engineers are a great career choice. They can easily move up to senior positions from their entry-level position. The best way to stand out in the field is to build a strong portfolio, which may include engineering projects, research, and articles. Facilities engineers should also continue to learn about their area of expertise. This will help them stand out when applying for a new position.

Even though certification is not necessary for all facilities engineers it can make a difference when you apply for a new job. A professional engineer should possess a broad knowledge of engineering principles and concepts, as well as the ability to analyze data and make compelling presentations. Facility engineers must have knowledge in areas such as predictive maintenance, asset reliability and maintenance strategies, as well the design of facilities.

Facility engineers work in offices, construction, and manufacturing environments. They are responsible for ensuring that utility systems run safely, efficiently, and effectively. Facilities engineers often work closely alongside other engineers and managers, helping to create efficient work routines and deal with any issues that might arise.

A facilities engineer's responsibilities will vary based on the size and type of facility he or she is assigned to work in. Typically, the job requires excellent time management skills, problem-solving abilities, and an ability to work well with others. During a typical day, a facilities engineer may perform hundreds of tasks. An engineer who is responsible for the maintenance and repair of electrical, mechanical and plumbing equipment must be capable of troubleshooting and fixing malfunctions.

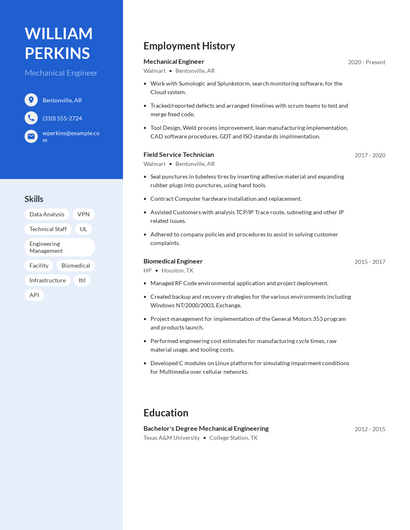

Many websites offer information and news about the field, including the Association of Facility Engineers' (AFE) website. These websites provide information such as a sample resume, salary information and articles about job opportunities.

Facilities engineers can also access these sites to read books, articles, take training courses and make connections with other engineers. For a successful facility engineer to succeed, you need to have organizational skills and a solid understanding about building and safety codes.

It's important to note that some of the most advanced facilities engineers are able to analyze data and perform a number of tasks at once. They need to be familiar with AutoCAD and other construction methods such as the CAM. You will also benefit from skills such as project management, critical thinking and problem solving.

One of the best things about a job in facilities engineering is the opportunity to work closely with a diverse group of people. Many of these engineers are trained to work with a variety of different materials and are able to coordinate the work of other engineers.

FAQ

What do you mean by warehouse?

A warehouse is an area where goods are stored before being sold. It can be an indoor space or an outdoor area. In some cases it could be both indoors and outdoors.

What are the 7 Rs of logistics?

The 7R's of Logistics is an acronym for the seven basic principles of logistics management. It was published in 2004 by the International Association of Business Logisticians as part of their "Seven Principles of Logistics Management" series.

The acronym is composed of the following letters.

-

Responsive - ensure all actions are legal and not harmful to others.

-

Reliable - You can have confidence that you will fulfill your promises.

-

Reasonable - make sure you use your resources well and don't waste them.

-

Realistic - Take into consideration all aspects of operations including cost-effectiveness, environmental impact, and other factors.

-

Respectful - Treat people fairly and equitably

-

Reliable - Find ways to save money and increase your productivity.

-

Recognizable - provide customers with value-added services.

What are the jobs in logistics?

There are many jobs available in logistics. Some of them are:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers, - They sort out and pack freight in warehouses.

-

Inventory managers: They are responsible for the inventory and management of warehouses.

-

Sales representatives: They sell products to customers.

-

Logistics coordinators - They organize and plan logistics operations.

-

Purchasing agents: They are responsible for purchasing goods and services to support company operations.

-

Customer service representatives - Answer calls and email from customers.

-

Shippers clerks - They process shipping order and issue bills.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors - They check incoming and outgoing products for defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

What are the four types in manufacturing?

Manufacturing refers to the transformation of raw materials into useful products by using machines and processes. Manufacturing can include many activities such as designing and building, testing, packaging shipping, selling, servicing, and other related activities.

What are the products of logistics?

Logistics are the activities involved in moving goods from point A to point B.

They cover all aspects of transportation, such as packing, loading, transporting and unloading.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They keep track and monitor the transit of shipments, maintain quality standards, order replenishment and inventories, coordinate with suppliers, vendors, and provide support for sales and marketing.

What is the distinction between Production Planning or Scheduling?

Production Planning (PP), or production planning, is the process by which you determine what products are needed at any given time. This can be done by forecasting demand and identifying production capabilities.

Scheduling is the process of assigning specific dates to tasks so they can be completed within the specified timeframe.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It is about eliminating defects and waste from all stages of the value stream. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Lean manufacturing is widely practiced in many industries around the world. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Lean manufacturing includes five basic principles:

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many businesses are now using lean manufacturing to improve their competitiveness. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include higher customer satisfaction, lower inventory levels, lower operating expenses, greater productivity, and improved overall safety.

The principles of lean manufacturing can be applied in almost any area of an organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three types of lean manufacturing.

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT refers to a system in which components are assembled at the point of use instead of being produced ahead of time. This approach is designed to reduce lead times and increase the availability of components. It also reduces inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. You should repair any part that needs to be repaired during an assembly line. This is true even for finished products that only require minor repairs prior to shipping.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous Improvement involves continuous improvement of processes.