The most fulfilling and interesting careers in logistics are those that you can find. There are many career options, from logistics operations and supply chain management to transport and logistics operations. While you will find employment opportunities in some of America's most dynamic and interesting neighborhoods like Uptown or West Loop, there are also opportunities available in the suburban areas. A Chicago logistics job is a great choice for anyone looking to start their career or advance in their field.

There are a number of companies in Chicago that are currently hiring. Echo Global Logistics (a leading provider in technology-enabled BPO) services is one of the most sought after. The company's proprietary web-based technology allows clients to achieve significant transportation savings. Additionally, its dedicated service teams work tirelessly to ensure client satisfaction.

In addition to its strong procurement power, Echo Global Logistics has a robust suite of service offerings and offers clients access to industry-leading transportation and logistics services. One example of Echo Global Logistics' clients includes a multinational warehouse located in Chicago's Bedford Park. The warehouse's web-based, proprietary technology allows it to manage shipments instantly, eliminating long-term imbalances and providing a better customer experience.

The city of Chicago is home to some of the country's most prestigious universities. Northwestern University, University of Illinois at Chicago (UIC), and University of Wisconsin Madison (UMM) are among the most highly regarded schools in the State. A number of vibrant cultural and entertainment centers are available to complement the outstanding academic programs. One of the most interesting areas is the Magnificent Mile area, which contains many of the city’s most beloved sights. The Loop, West Loop and Gold Coast are some other popular neighborhoods. There you'll find an assortment of the finest restaurants around the globe.

Having a well-rounded education is a must. Although many people work in logistics without any formal education, it's still a good idea for those who are serious to pursue a degree in the field you are most interested in. It will be helpful to have a degree in business, supply chain management, entrepreneurship or accounting. You may need a degree in these areas depending on what company you work for to secure a high-paying job. However, if you can't afford to take on a full-time MBA program, there are a number of online degree programs that offer bachelor and master's level courses.

Take a look at the company’s website if you are interested in a career within logistics. You should also read about the company's procedures and rewards. It will pay off. You'll enjoy a more rewarding and successful career. You'll also be in a safe place.

With some hard work and a little luck you could also find some of the most desirable jobs in the city. You won't get to the top of this ladder overnight. Your job may be based on location or business needs, so make sure you keep a flexible schedule.

FAQ

What is the difference between a production planner and a project manager?

The primary difference between a producer planner and a manager of a project is that the manager usually plans and organizes the whole project, while a production planner is only involved in the planning stage.

What does it take for a logistics enterprise to succeed?

It takes a lot of skills and knowledge to run a successful logistics business. Effective communication skills are necessary to work with suppliers and clients. You should be able analyse data and draw inferences. You will need to be able handle pressure well and work in stressful situations. To improve efficiency, you must be innovative and creative. You need to have strong leadership qualities to motivate team members and direct them towards achieving organizational goals.

It is important to be organized and efficient in order to meet tight deadlines.

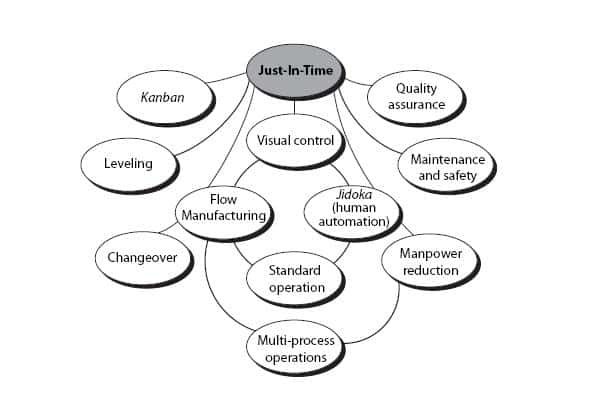

Can some manufacturing processes be automated?

Yes! Yes! Automation has existed since ancient times. The Egyptians invent the wheel thousands of year ago. Today, robots assist in the assembly of lines.

In fact, there are several applications of robotics in manufacturing today. They include:

-

Line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Automation could also be used to improve manufacturing. 3D printing makes it possible to produce custom products in a matter of days or weeks.

What is the responsibility of a manufacturing manager?

A manufacturing manager has to ensure that all manufacturing processes work efficiently and effectively. They should also be aware and responsive to any company problems.

They should also learn how to communicate effectively with other departments, including sales and marketing.

They should also be aware of the latest trends in their industry and be able to use this information to help improve productivity and efficiency.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

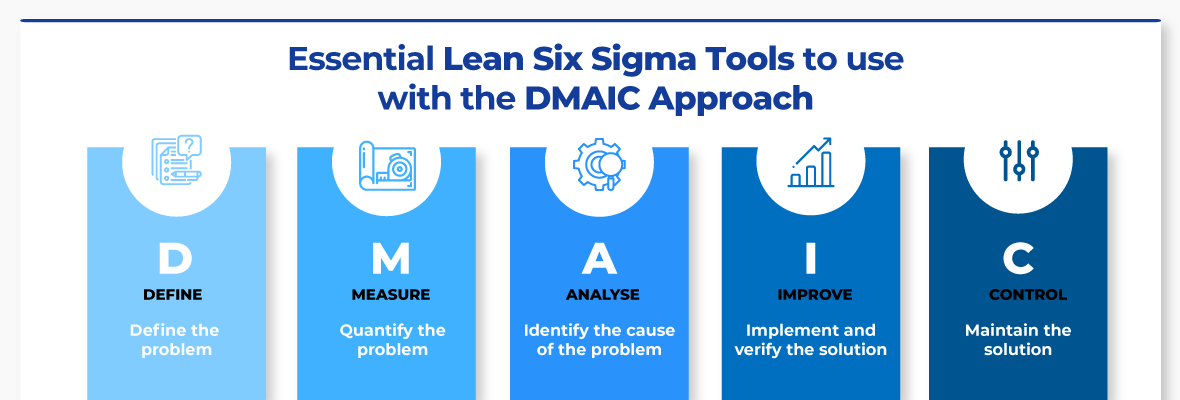

Six Sigma and Manufacturing

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. The main goal of Six Sigma is to reduce variation from the mean value of production. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If this deviation is too big, you know something needs fixing.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you understand this, you can then identify the causes of variation. This will allow you to decide if these variations are random and systematic. Random variations occur when people do mistakes. Symmetrical variations are caused due to factors beyond the process. For example, if you're making widgets, and some of them fall off the assembly line, those would be considered random variations. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

Once you've identified the problem areas you need to find solutions. The solution could involve changing how you do things, or redesigning your entire process. You should then test the changes again after they have been implemented. If they fail, you can go back to the drawing board to come up with a different plan.