Toyota has maintained its focus on quality, despite all its successes. Toyota has been a top-selling automotive brand because of its unwavering dedication to excellence.

Toyota's strategy is based on staying true to its core values, focusing on incremental innovations, and promoting smart growth. It also stresses the importance of building and nurturing relationships with its dealers. Toyota puts its customers ahead of other companies, even though they may rely on stock prices. This is because the automobile industry is highly competitive and a company's success depends on its ability to innovate.

Toyota employees must be able to face challenges in order to continue to achieve success. To overcome these challenges, Toyota encourages employees to experiment and develop new ideas. Employees are encouraged to communicate openly and challenged to make compromises and transcend differences. On-the-job training is a way to achieve this. Employees are encouraged to share their mistakes and problems.

Another way Toyota manages to succeed is through the use of a "continuous improvement" process, called kaizen. The process involves streamlining processes and testing new ideas. This process, known in Japanese as "genchi genbutsu", helps Toyota achieve its goals. It is an integral part Toyota’s culture. It has been the core of Toyota's success since decades.

One of the first major moves that Toyota made was to establish a research lab. Its founder, Kiichiro Toyoda, believed that if the automobile industry was to remain competitive, it would need to develop new technologies from scratch. In the 1930s, he established a research laboratory. He dreamed of a Japan that could produce automobiles and other technology independently.

In the 1950s, Toyota made a series of strategic moves. It started diversifying its product line and exporting cars all over the globe. It established a separate sales organization and a network for dealers. It also began to develop an understanding of the international automobile market. It was able to see that American and European automakers would overtake Toyota if Toyota attempted to compete in the global market.

Toyota also made a major decision in the '50s to create an American division. Because it saw that American workers were nine-times more productive than Japanese workers, the company made this move. It also realised that the market was demanding fuel-efficient cars. In the United States, it had to convince the public that Japanese cars were a good investment. It had to overcome the major strike that decimated the company in 1950s. It needed to get loans and lay off staff.

Toyota also created a "driving school", which assists citizens in obtaining their drivers' licenses. It also created a line of cars specifically for the U.S. market. These initiatives were a great way to bring customers into the dealerships.

Toyota's success within the automotive industry is dependent on its ability innovate and create value. It depends also on its ability and willingness to build relationships with suppliers and dealers.

FAQ

What are the requirements to start a logistics business?

A successful logistics business requires a lot more than just knowledge. Effective communication skills are necessary to work with suppliers and clients. You need to understand how to analyze data and draw conclusions from it. You will need to be able handle pressure well and work in stressful situations. You need to be innovative and creative to come up with new ways to increase efficiency. You need to have strong leadership qualities to motivate team members and direct them towards achieving organizational goals.

It is also important to be efficient and well organized in order meet deadlines.

What skills is required for a production planner?

You must be flexible and organized to become a productive production planner. You must also be able to communicate effectively with clients and colleagues.

What is the responsibility for a logistics manager

A logistics manager makes sure that all goods are delivered on-time and in good condition. This is done through his/her expertise and knowledge about the company's product range. He/she must also ensure sufficient stock to meet the demand.

What does it mean to be a manufacturer?

Manufacturing Industries is a group of businesses that produce goods for sale. Consumers are the people who purchase these products. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. They manufacture goods from raw materials using machines and other equipment. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

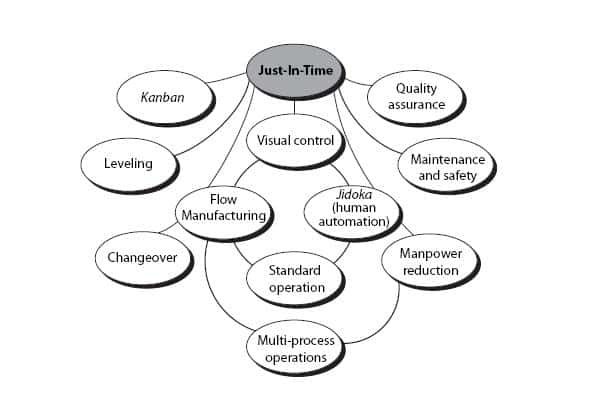

How to use the Just In-Time Production Method

Just-intime (JIT), which is a method to minimize costs and maximize efficiency in business process, is one way. This is where you have the right resources at the right time. This means that only what you use is charged to your account. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He saw how overtime was paid to workers for work that was delayed. He concluded that if workers were given enough time before they start work, productivity would increase.

The idea behind JIT is that you should plan ahead and have everything ready so you don't waste money. The entire project should be looked at from start to finish. You need to ensure you have enough resources to tackle any issues that might arise. You will have the resources and people to solve any problems you anticipate. You won't have to pay more for unnecessary items.

There are many JIT methods.

-

Demand-driven: This JIT is where you place regular orders for the parts/materials that are needed for your project. This will let you track the amount of material left over after you've used it. This will let you know how long it will be to produce more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you predict the amount you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. If you know the amount you require, you can buy the materials you need.

-

Resource-based JIT : This is probably the most popular type of JIT. You assign certain resources based off demand. If you have many orders, you will assign more people to manage them. If you don’t have many orders you will assign less people to the work.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based - This is a variant of cost-based. But instead of looking at the total company cost, you focus on how much raw material you spend per year.

-

Time-based: Another variation of resource-based JIT. Instead of focusing only on how much each employee is costing, you should focus on how long it takes to complete your project.

-

Quality-based: This is yet another variation of resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based: This is one of the newest forms of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, your goal is to add value to the market.

-

Stock-based. This method is inventory-based and focuses only on the actual production at any given point. It is used when production goals are met while inventory is kept to a minimum.

-

Just-intime (JIT), planning is a combination JIT management and supply chain management. It refers to the process of scheduling the delivery of components as soon as they are ordered. It is essential because it reduces lead-times and increases throughput.