Oracle Supply Chain Management offers a comprehensive solution that enables organizations to respond quickly to changes, build resilient networks, improve forecast accuracy, and adapt quickly in the face of changing circumstances. Oracle SCM offers flexible supply chain planning, which improves collaboration and reduces costs. With Oracle Fusion Cloud SCM, you can use this solution to optimize your business processes and collaborate more effectively with your suppliers. Oracle SCM can help achieve these goals by reducing disruptions, reducing cost, and improving forecast accuracy.

User-friendly interface

Many of the new features in Oracle SCM can be attributed to the improved user interface. This new release makes the system more accessible and user-friendly. An analysis script that is product-based provides early warnings, solutions, and recommendations. The Oracle Inbound Transactions Analyzer is a great example of this. It can identify inbound transaction issues and provide solutions. It is also highly customizable.

Cost management

Oracle SCM can help you define cost management policies and make decisions at the item-level. Cost profiles can be differentiated according to product and manufacturing processes, rather than using the same costing methodology across all items. For instance, manufactured items might be driven by a standard roll-up cost while repair items will use an actual costing method. The software also supports multiple open and closed periods. In addition, it supports cost simulation and copying capabilities.

Support for decision making

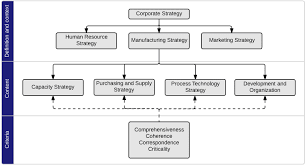

Oracle SCM uses advanced analytics to support decision making. Using a comprehensive set of business intelligence tools, management can determine the best course of action based on data and information. Oracle Strategic Enterprise Management is designed to support strategic management techniques in many organizations. Executives can use this technology to control costs and measure progress against a set plan. Employee performance can be measured and compensated. These integrated enterprise-wide applications complement Oracle's ERP systems.

Regulatory compliance

As regulatory compliance laws and regulations continue to increase, organizations need to find effective ways to manage them. Oracle has the solution. Oracle SCM regulatory compliance solutions allow organizations to more easily meet legal and regulatory compliance needs. The Oracle Cloud Platform provides flexible deployment options for organizations of all sizes. Oracle offers a range of configurable, customizable products that can be customized to meet regulatory compliance requirements.

Flexible solution

Intellinum Inc., a world-renowned provider of supply chain mobility services, has created Flexi LogiPro. It is a flexible solution that supports Oracle SCM Cloud and Oracle WMS cloud. The mobile solution is customizable and barcode-enabled. It can integrate with the backend system instantly and supports Oracle SCM Cloud and WMS cloud. It is available for both cloud and on-premise deployments, and enables companies to personalize their mobile apps for the specific needs of their organizations.

FAQ

What is production management?

Production Planning includes planning for all aspects related to production. This document will ensure everything is in order and ready to go when you need it. It should also provide information about how best to produce the best results while on set. This includes location information, crew details, equipment specifications, and casting lists.

It is important to first outline the type of film you would like to make. You may have decided where to shoot or even specific locations you want to use. Once you have identified the scenes and locations, you can start to determine which elements are required for each scene. You might decide you need a car, but not sure what make or model. In this case, you could start looking up cars online to find out what models are available and then narrow your choices by choosing between different makes and models.

Once you have found the right vehicle, you can think about adding accessories. Do you need people sitting in the front seats? Or maybe you just need someone to push the car around. You might want to change your interior color from black and white. These questions will help you determine the exact look and feel of your car. Another thing you can do is think about what type of shots are desired. Do you want to film close-ups, or wider angles? Maybe you want to show your engine or the steering wheel. These things will help you to identify the car that you are looking for.

Once you have determined all of the above, you can move on to creating a schedule. A schedule will tell you when you need to start shooting and when you need to finish. A schedule for each day will detail when you should arrive at the location and when you need leave. Everyone knows exactly what they should do and when. Hire extra staff by booking them ahead of time. You don't want to hire someone who won't show up because he didn't know.

When creating your schedule, you will also need to consider the number of days you need to film. Some projects take only a few days while others can last several weeks. While creating your schedule, it is important to remember whether you will require more than one shot per day. Multiple shots at the same location can increase costs and make it more difficult to complete. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Another important aspect of production planning is setting budgets. A realistic budget will help you work within your means. It is possible to reduce the budget at any time if you experience unexpected problems. However, you shouldn't overestimate the amount of money you will spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Production planning is a detailed process. But, once you understand the workings of everything, it becomes easier for future projects to be planned.

Is there anything we should know about Manufacturing Processes prior to learning about Logistics.

No. No. But, being familiar with manufacturing processes will give you a better understanding about how logistics works.

How important is automation in manufacturing?

Automating is not just important for manufacturers, but also for service providers. They can provide services more quickly and efficiently thanks to automation. In addition, it helps them reduce costs by reducing human errors and improving productivity.

What is the role of a production manager?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They also ensure the quality of the product and service meets the client's requirements.

What are manufacturing and logistics?

Manufacturing refers to the process of making goods using raw materials and machines. Logistics covers all aspects involved in managing supply chains, including procurement and production planning. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

Why automate your warehouse

Automation has become increasingly important in modern warehousing. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses have to be flexible to meet changing requirements. They must invest heavily in technology to do this. The benefits of automating warehouses are numerous. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety Boosts

-

Eliminates bottlenecks

-

Companies can scale up more easily

-

Workers are more productive

-

Gives you visibility into all that is happening in your warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Reducing downtime and increasing uptime

-

This ensures that quality products are delivered promptly

-

Eliminates human error

-

This helps to ensure compliance with regulations

Can some manufacturing processes be automated?

Yes! Yes. Automation has been around since ancient time. The wheel was invented by the Egyptians thousands of years ago. We now use robots to help us with assembly lines.

Actually, robotics can be used in manufacturing for many purposes. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that produce products

Manufacturing could also benefit from automation in other ways. 3D printing, for example, allows us to create custom products without waiting for them to be made.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to Use the Just In Time Method in Production

Just-in-time (JIT) is a method that is used to reduce costs and maximize efficiency in business processes. It's the process of obtaining the right amount and timing of resources when you need them. This means that your only pay for the resources you actually use. Frederick Taylor was the first to coin this term. He developed it while working as a foreman during the early 1900s. After observing how workers were paid overtime for late work, he realized that overtime was a common practice. He decided that workers would be more productive if they had enough time to complete their work before they started to work.

The idea behind JIT is that you should plan ahead and have everything ready so you don't waste money. Look at your entire project, from start to end. Make sure you have enough resources in place to deal with any unexpected problems. If you expect problems to arise, you will be able to provide the necessary equipment and personnel to address them. This will ensure that you don't spend more money on things that aren't necessary.

There are many JIT methods.

-

Demand-driven: This is a type of JIT where you order the parts/materials needed for your project regularly. This will let you track the amount of material left over after you've used it. It will also allow you to predict how long it takes to produce more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you to forecast how much you will sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT: This is the most popular form of JIT. You assign certain resources based off demand. For example, if there is a lot of work coming in, you will have more people assigned to them. If you don’t have many orders you will assign less people to the work.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based JIT is another form of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based JIT: Another variation on resource-based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based JIT is the newest form of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, you focus on the added value that you provide to your market.

-

Stock-based: This inventory-based approach focuses on how many items are being produced at any one time. This is used to increase production and minimize inventory.

-

Just-intime (JIT), planning is a combination JIT management and supply chain management. It is the process that schedules the delivery of components within a short time of their order. It's important as it reduces leadtimes and increases throughput.