Orlando is home of a number top logistics companies that provide services to both small and large businesses. You can start a career here in a number of different ways, from entry level positions to managerial roles that pay well over $100,000 annually.

There are many different types of jobs in logistics available in Orlando. These include truck drivers, shipping clerks and warehouse associates. You can gain experience in many different areas with these jobs, including planning and organizing large jobs or overseeing a company's day-to-day operation.

Orlando has an industry worth $1.5 billion that is dedicated to moving goods. The city is known for its central location, and as a result, it's home to several major shipping hubs.

These hubs enable companies in Orlando to reach out to a variety of clients. The hubs make it easier for businesses to transport goods from around the globe and across the country.

For those who want to work as a logistician, there are certain things they should know. For starters, you'll need to know how to manage a large volume of cargo. You can negotiate contracts and ensure that the correct supplies are delivered to the appropriate people at the proper time.

Know about the security and safety measures of the cargos you transport. Orlando's leading logistics firms offer advanced tracking and security technology, along with cargo certifications.

You should also check the reputation of the company and its customer service before selecting them to handle your logistical needs. Reviewing reviews and feedback of other customers as well as talking with company representatives can help you do this.

The best logistics companies in Orlando will have a strong reputation and a great track record for reliability and quality service. They should provide their customers with accurate and reliable information and offer shipping and delivery services that are competitively priced.

AIT and Roadrunner Transportation Systems are three of the top logistics companies in Orlando. These companies all focus on helping small- to medium size businesses ship smarter.

These logistics companies offer many services, including inventory management, shipping, and supply chain management. You can also get a 24 hour service that will meet your needs even after working hours.

Orlando shipping firms should be capable of handling any job. They should also be equipped with the necessary staff and equipment to handle all types of moves, no matter how large or little.

Orlando has a large and skilled workforce, making it an ideal destination for logistics. There are also many transportation options available, such as air, sea and rail. It is a great location for any logistics company who wants to be near the most popular destinations in the country.

FAQ

What jobs are available in logistics?

There are many kinds of jobs available within logistics. Here are some examples:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers: They sort and package freight in warehouses.

-

Inventory managers - They oversee the inventory of goods in warehouses.

-

Sales representatives - They sell products.

-

Logistics coordinators are responsible for organizing and planning logistics operations.

-

Purchasing agents: They are responsible for purchasing goods and services to support company operations.

-

Customer service representatives - They answer calls and emails from customers.

-

Shippers clerks - They process shipping order and issue bills.

-

Order fillers - They fill orders based on what is ordered and shipped.

-

Quality control inspectors - They check incoming and outgoing products for defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

What are the 4 types manufacturing?

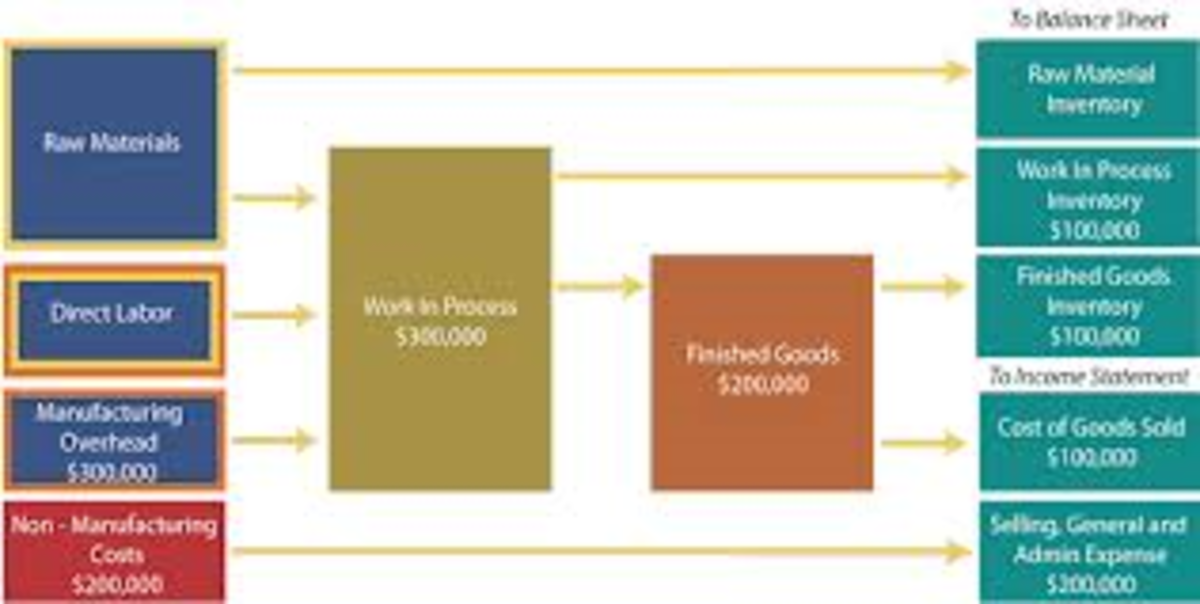

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. Manufacturing involves many activities, including designing, building, testing and packaging, shipping, selling, service, and so on.

How can manufacturing efficiency improved?

First, we need to identify which factors are most critical in affecting production times. The next step is to identify the most important factors that affect production time. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you've identified them all, find solutions to each one.

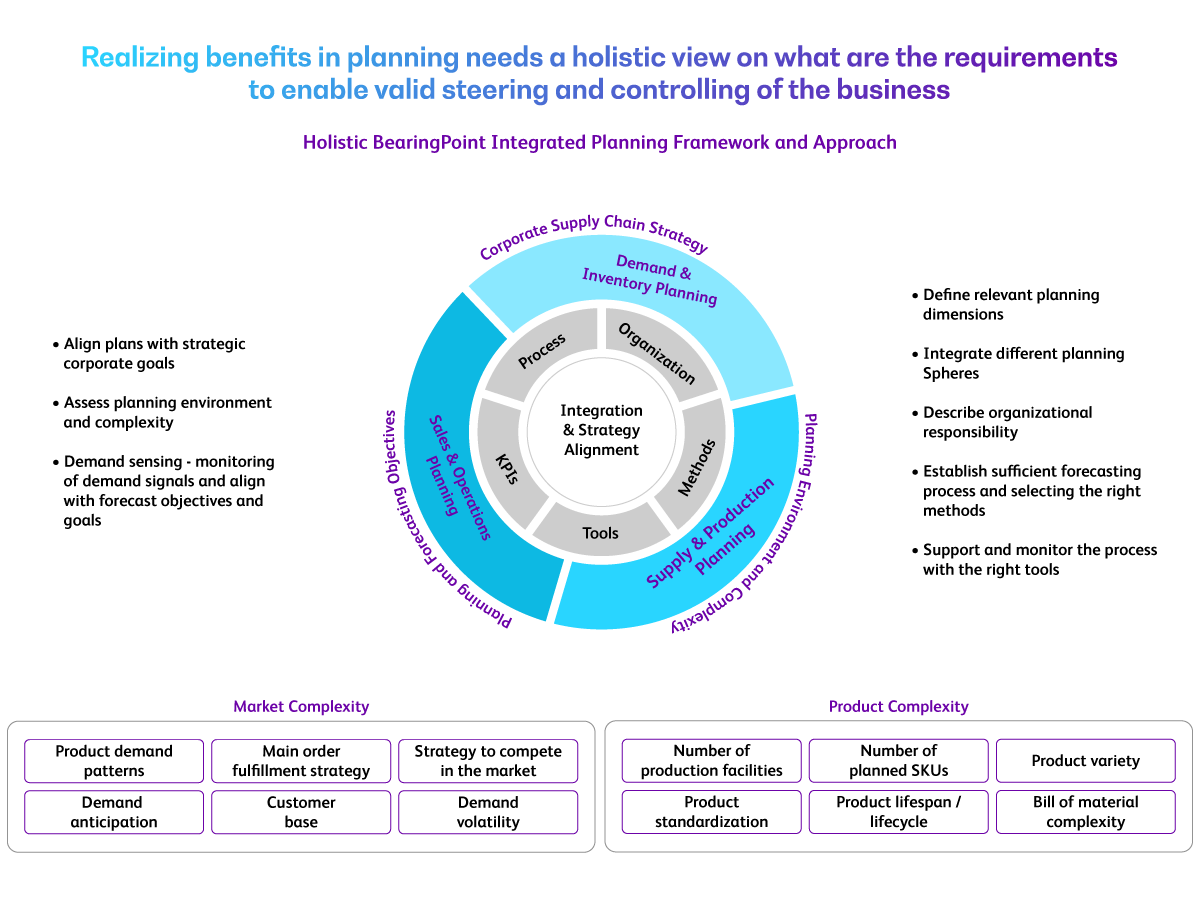

What's the difference between Production Planning & Scheduling?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. This can be done by forecasting demand and identifying production capabilities.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

What is the job of a production plan?

Production planners ensure all aspects of the project are delivered within time and budget. They also ensure that the product/service meets the client’s needs.

How can we reduce manufacturing overproduction?

The key to reducing overproduction lies in developing better ways to manage inventory. This would reduce time spent on activities such as purchasing, stocking, and maintaining excess stock. This would allow us to use our resources for more productive tasks.

A Kanban system is one way to achieve this. A Kanban board can be used to monitor work progress. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state is assigned a different priority.

For instance, when work moves from one stage to another, the current task is complete enough to be moved to the next stage. However, if a task is still at the beginning stages, it will remain so until it reaches the end of the process.

This allows you to keep work moving along while making sure that no work gets neglected. Managers can view the Kanban board to see how much work they have done. This data allows them adjust their workflow based upon real-time data.

Lean manufacturing is another way to manage inventory levels. Lean manufacturing seeks to eliminate waste from every step of the production cycle. Anything that does nothing to add value to a product is waste. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Overstock materials

These ideas will help manufacturers increase efficiency and lower costs.

Can certain manufacturing steps be automated?

Yes! Yes. The Egyptians discovered the wheel thousands and years ago. Today, robots assist in the assembly of lines.

There are many uses of robotics today in manufacturing. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

Manufacturing could also benefit from automation in other ways. 3D printing makes it possible to produce custom products in a matter of days or weeks.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to use the Just In-Time Production Method

Just-in-time is a way to cut costs and increase efficiency in business processes. It's the process of obtaining the right amount and timing of resources when you need them. This means that your only pay for the resources you actually use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He observed how workers were paid overtime if there were delays in their work. He concluded that if workers were given enough time before they start work, productivity would increase.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. Also, you should look at the whole project from start-to-finish and make sure you have the resources necessary to address any issues. If you expect problems to arise, you will be able to provide the necessary equipment and personnel to address them. This way, you won't end up paying extra money for things that weren't really necessary.

There are different types of JIT methods:

-

Demand-driven JIT: You order the parts and materials you need for your project every other day. This will let you track the amount of material left over after you've used it. This will let you know how long it will be to produce more.

-

Inventory-based: This type allows you to stock the materials needed for your projects ahead of time. This allows you to forecast how much you will sell.

-

Project-driven: This method allows you to set aside enough funds for your project. You will be able to purchase the right amount of materials if you know what you need.

-

Resource-based JIT: This type of JIT is most commonly used. This is where you assign resources based upon demand. You will, for example, assign more staff to deal with large orders. You'll have fewer orders if you have fewer.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based JIT is another form of resource-based JIT. Instead of worrying about how much each worker costs, you can focus on how long the project takes.

-

Quality-based JIT: Another variation on resource-based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based: This is one of the newest forms of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, your focus is on the value you bring to the market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It is used when production goals are met while inventory is kept to a minimum.

-

Just-in-time (JIT) planning: This is a combination of JIT and supply chain management. It is the process of scheduling components' delivery as soon as they have been ordered. It's important because it reduces lead times and increases throughput.