A director in manufacturing is responsible to manage the company's production processes. As they are responsible for managing the entire production process, their role is critical. The ideal candidate should have extensive manufacturing experience and be proficient in new technologies in order to succeed in this position. Examples of such technologies are robotics and 3-D printing. An asset to any company is a director who can keep up with new technologies. As the manufacturing industry evolves, the director's job will be more complex. He or she will have to coordinate with both the engineering and operations departments.

Salary for a Director of Manufacturing

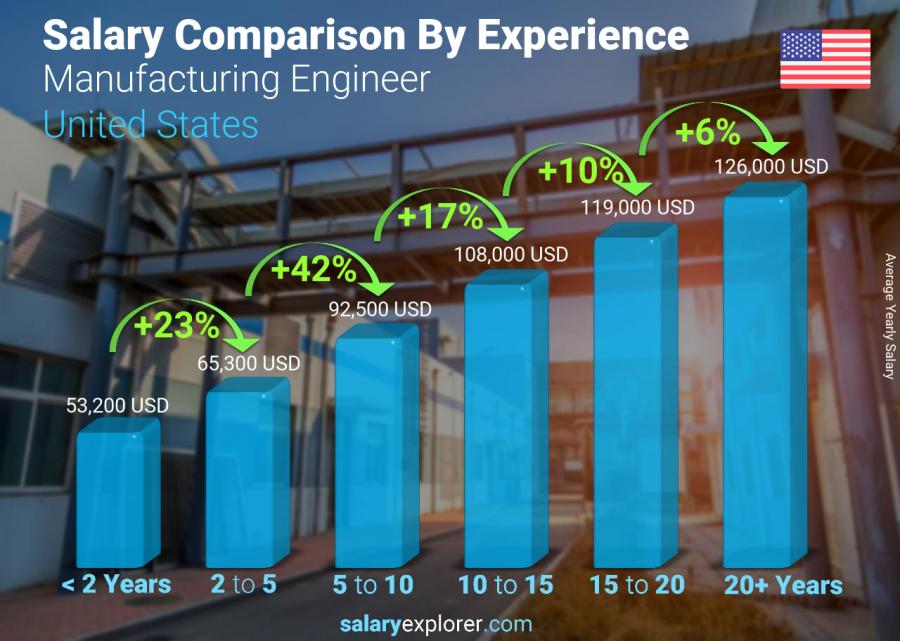

The salary of a Director of Manufacturing can vary depending on where they are located. Director of Manufacturing salaries can range from low to mid-six figures. However, some directors earn considerably more than others. The salary of a Director of Manufacturing may also vary significantly based on years of experience and education. Here are some factors that could impact your salary.

Although the salary for a Director of Manufacturing can vary depending on your experience, the average salary is higher. Salary can be affected depending on where you live and how much it costs to live. If you live in a big city, expect to earn higher salaries, but be aware that your salary may not match the cost of living. Always be willing to negotiate for a higher salary, if offered.

The annual salary of a Director of Manufacturing Operations is between $181,500 to $66,000. The salary of a Director Manufacturing Operations is highly variable. It can vary by up 8% among different cities. The average salary for a director of manufacturing operations in Fremont is $128,493 to $164,500. This is significantly higher than the national average. The salary of a Director in Manufacturing Operations can vary depending on where you live, how experienced you are, and what company you work for.

Education required

The director of manufacturing oversees the management and production of a facility. This job includes managing new employees, quality assurance, working with designers and meeting production standards. A director of manufacturing typically reports to the senior management team and executes policy and sales initiatives. Candidates must have experience in manufacturing and communicate well. Companies have different requirements when it comes to education.

Although a master's degree in engineering does not necessarily make you a director in manufacturing, having a post-secondary education is a great way to increase your knowledge and skill set. An MBA program in industrial management or business administration is a great choice for this position, as it helps candidates to learn about management, economics, and organization. In the end, you will manage a diverse team of people.

As a director manufacturing, you will closely work with designers and engineers in the product development phase. You will participate in the evaluation of new processes and setting quality standards before investing resources into larger productions. Successful directors also play a role as coaches and mentors for employees. They will guide them in risk mitigation and best practice. Manufacturing directors are responsible for overseeing all aspects of production and must also have problem-solving skills.

Experience required

A bachelor's degree in a relevant field and five to 10 years of progressive work experience are often necessary for this position. For this position, manufacturing companies prefer to recruit internal employees. The ideal candidate must have a deep understanding of the manufacturing industry and its business goals. Employers may want to see a graduate level. These requirements may not be sufficient. Candidates may need to have additional training in their chosen industry or field.

A director of manufacturing oversees the production process, including engineers, supervisors, and workers. They may be responsible for solving problems and developing a solution for them. They might also be responsible to develop and implement quality control programs. Directly reports to the top management of the manufacturing organization, the director of manufacturing. Experience in manufacturing is an absolute must. Manufacturing management experience can make you a success in this role.

Experience as a manufacturing director will be an asset. Directors must have at the least 10 years relevant experience working in a manufacturing environment. They might have begun their careers as technicians or manufacturing supervisors. They must also be able to communicate well. The director of manufacturing must also be able to understand business strategy. Finally, a director of manufacturing must be able to work effectively with other departments within the organization. In this capacity, the director oversees the production process and ensures that it meets the highest quality standards.

FAQ

What is the job of a logistics manger?

Logistics managers are responsible for ensuring that all goods arrive in perfect condition and on time. This is done by using his/her experience and knowledge of the company's products. He/she should make sure that enough stock is on hand to meet the demands.

What does it take to run a logistics business?

A successful logistics business requires a lot more than just knowledge. For clients and suppliers to be successful, you need to have excellent communication skills. It is important to be able to analyse data and draw conclusions. You must be able and able to handle stress situations and work under pressure. You need to be innovative and creative to come up with new ways to increase efficiency. Strong leadership qualities are essential to motivate your team and help them achieve their organizational goals.

You should also be organized and efficient to meet tight deadlines.

What skills does a production planner need?

You must be flexible and organized to become a productive production planner. Effective communication with clients and colleagues is essential.

What is the difference in Production Planning and Scheduling, you ask?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. This is accomplished by forecasting the demand and identifying production resources.

Scheduling is the process of assigning specific dates to tasks so they can be completed within the specified timeframe.

How can manufacturing efficiency improved?

First, identify the factors that affect production time. Next, we must find ways to improve those factors. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you've identified them, try to find solutions for each of those factors.

What is production planning?

Production Planning is the creation of a plan to cover all aspects, such as scheduling, budgeting. Location, crew, equipment, props and other details. This document will ensure everything is in order and ready to go when you need it. You should also have information to ensure the best possible results on set. This includes information on shooting times, locations, cast lists and crew details.

The first step is to decide what you want. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have identified your locations and scenes it's time to begin figuring out what elements you will need for each one. One example is if you are unsure of the exact model you want but decide that you require a car. In this case, you could start looking up cars online to find out what models are available and then narrow your choices by choosing between different makes and models.

After you've found the perfect car, it's time to start thinking about adding extras. Do you need people sitting in the front seats? You might also need someone to help you get around the back. You might want to change your interior color from black and white. These questions will help to determine the style and feel of your car. The type of shots that you are looking for is another thing to consider. Will you be filming close-ups or wide angles? Perhaps you want to show the engine or the steering wheel? These details will help identify the exact car you wish to film.

Once you've determined the above, it is time to start creating a calendar. A schedule will tell you when you need to start shooting and when you need to finish. You will need to know when you have to be there, what time you have to leave and when your return home. It will help everyone know exactly what they have to do and when. Book extra staff ahead of time if you need them. It is not worth hiring someone who won’t show up because you didn’t tell him.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects take only a few days while others can last several weeks. When creating your schedule, be aware of whether you need more shots per day. Shooting multiple takes over the same location will increase costs and take longer to complete. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Budgeting is another crucial aspect of production plan. It is important to set a realistic budget so you can work within your budget. Keep in mind that you can always reduce your budget if you face unexpected difficulties. However, you shouldn't overestimate the amount of money you will spend. Underestimating the cost will result in less money after you have paid for other items.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the "The Machine That Changed the World", the first book about lean manufacturing. It was published in 1990.

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It emphasizes reducing defects and eliminating waste throughout the value chain. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

In addition to improving product quality and reducing costs, lean manufacturing helps companies achieve their goals faster and reduces employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Many industries worldwide use lean manufacturing. Toyota's philosophy has been a key driver of success in many industries, including automobiles and electronics.

Lean manufacturing includes five basic principles:

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Although lean manufacturing has always been around, it is gaining popularity in recent years because of a renewed interest for the economy after 2008's global financial crisis. Many companies have adopted lean manufacturing methods to increase their marketability. In fact, some economists believe that lean manufacturing will be an important factor in economic recovery.

Lean manufacturing, which has many benefits, is now a standard practice in the automotive industry. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

You can apply Lean Manufacturing to virtually any aspect of your organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three main types:

-

Just-in-Time Manufacturing (JIT): This type of lean manufacturing is commonly referred to as "pull systems." JIT means that components are assembled at the time of use and not manufactured in advance. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.