Industrial engineers are responsible for designing efficient systems that integrate people, machines, materials and information to create a product, or provide a particular service. Industrial engineers may work at an office or a production facility, like a warehouse or manufacturing plant.

Industrial Engineer Entry in Texas

As an industrial engineer, you will be responsible for ensuring that production processes are running smoothly. You will be responsible for analyzing problems, troubleshooting and implementing improvements to increase efficiency. You may be asked to train and support technicians that use the systems or equipment you designed.

The type of company that you work for will determine your job duties. You might be required by certain manufacturers to develop a way of handling hazardous waste. Some require you to design a system of monitoring and controlling raw materials.

The manufacturers are always searching for ways to improve efficiency and reduce costs, so it is possible that you will be assigned to projects that aim to reduce the waste produced in production. It may be necessary to reduce the amount of stock in a warehouse or improve the efficiency on machinery.

You might work for a transportation equipment manufacturer or a computer and electronics firm. These jobs are generally full-time, and employment is projected to grow by 10% over the next decade.

Manufacturing Engineering Jobs Texas

Start your career in industrial engineering by taking a job at a company that makes heavy machinery, or energy equipment. This is a great way to learn about industrial engineering, and many plant managers seek out candidates with this experience.

During your time at the plant, you will be expected to participate in training programs and seminars. You will be able to become a better member of the team by participating in these training programs. You may also be asked to conduct specialized research, which helps you improve your skills as an Industrial Engineer.

Eastman Company Manufacturing Engineer

You may be offered a job as an industrial engineering at Eastman Chemical Mcallen in Texas if your skills match the requirements. This is a fast-paced and rewarding position that offers the opportunity to work at a leading technology and energy company.

As an industrial engineer, you will be responsible implementing and maintaining engineered labor standards for distribution centers across the country. You will work as a member of the industrial engineer team and be responsible for the presentation and distribution of engineering labor standards at the facilities.

FAQ

What are manufacturing and logistic?

Manufacturing refers the process of producing goods from raw materials through machines and processes. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

What does "warehouse" mean?

A warehouse is an area where goods are stored before being sold. You can have it indoors or outdoors. It could be one or both.

What are my options for learning more about manufacturing

Practical experience is the best way of learning about manufacturing. You can read books, or watch instructional videos if you don't have the opportunity to do so.

How can manufacturing efficiency be improved?

The first step is to identify the most important factors affecting production time. We then need to figure out how to improve these variables. If you don’t know how to start, look at which factors have the greatest impact upon production time. Once you identify them, look for solutions.

What is the difference between Production Planning and Scheduling?

Production Planning (PP) is the process of determining what needs to be produced at any given point in time. Forecasting and identifying production capacity are two key elements to this process.

Scheduling is the process of assigning specific dates to tasks so they can be completed within the specified timeframe.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

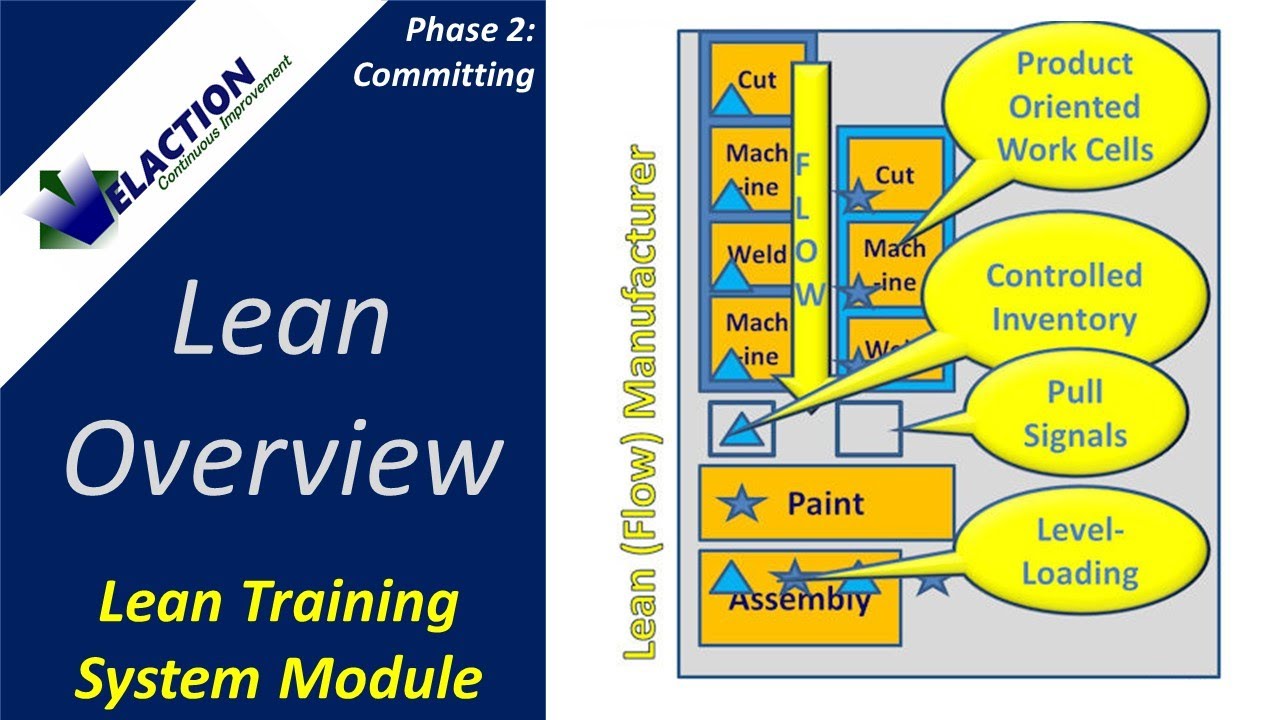

How to use lean manufacturing in the production of goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing refers to a set of principles that improve the quality, speed and costs of products and services. It emphasizes the elimination and minimization of waste in the value stream. Just-in-time (JIT), zero defect (TPM), and 5S are all examples of lean manufacturing. Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Many industries worldwide use lean manufacturing. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Five fundamental principles underlie lean manufacturing.

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Develop Relationships: Establish personal relationships both with internal and external stakeholders.

Although lean manufacturing isn't a new concept in business, it has gained popularity due to renewed interest in the economy after the 2008 global financial crisis. To increase their competitiveness, many businesses have turned to lean manufacturing. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing, which has many benefits, is now a standard practice in the automotive industry. These include higher customer satisfaction, lower inventory levels, lower operating expenses, greater productivity, and improved overall safety.

Lean manufacturing can be applied to almost every aspect of an organization. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three types of lean manufacturing.

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT stands for a system where components are assembled on the spot rather than being made in advance. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This is true even for finished products that only require minor repairs prior to shipping.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous improvement refers to continuous improvement of processes as well people and tools.