Manufacturing companies produce a wide range of products that can be used by businesses and consumers using a variety of components and raw materials. They produce products for daily use as well as heavy equipment and precision-metal components. In recent years, the manufacturing industry has experienced strong growth.

One of the most notable trends is the growth of electronic products. In the past few decades, this industry has seen a 32,000 increase in jobs. Companies are also hiring for manufacturing jobs within the metals sector.

Manufacturers are increasingly looking for local manufacturing as the economy improves. The government is working to increase American manufacturing's competitiveness. These include a "America First" trade policy and reducing regulations. The government plans to spend $1 trillion on infrastructure reconstruction. These investments will also aid manufacturers in their competition with facilities offshore.

In the manufacturing industry, innovation has always been a driving factor. The industry has been revolutionized by new technologies. One example is the creation of virtual prototyping, which allows companies to test products before making them. Advanced sensors is another option. This could improve the quality of American-made products. Companies are also looking to maximize their resources and cut costs.

Space technology is another important area of innovation. To develop future technologies, the government is working with academia as well as industry. New space technologies can improve life on Earth. These technologies can also be used to boost economic growth in specific regions. The government is also collaborating with the private sector to develop technologies for manufacturing in space.

The USA's industrial sector is huge. It contributes almost $600billion to the U.S. economy each year. Additionally, production is at an all-time high. The 2020 manufacturing industry is expected grow by 2.0%. Manufacturers should now be looking at new space technologies.

Manufacturing in space is a great opportunity for the country. The United States could benefit from new space technologies that not only improve our lives on Earth but also allow us to compete in the global market. New institutes are able to create advanced machine tools or materials for harsh service environments. This is a great way for manufacturers reduce risk.

Manufacturing USA Institutes, which are 16 innovation centers in manufacturing, are sponsored and managed by the Departments of Energy, Energy, Defense, Commerce, and Commerce. They are intended to encourage innovation by connecting people, ideas, and technology. Over 500 of their major R&D projects have been completed. They have also collaborated with more than 2000 member organizations. They have also involved over 70,000 people with advanced manufacturing activities.

The Manufacturing USA Institutes are also responsible for connecting the dots. They collaborate with other top technology and manufacturing research organisations. These organizations are also able to provide customized technology and market information. This can help companies determine which technologies and research programs are most relevant for their needs.

FAQ

What are the goods of logistics?

Logistics is the process of moving goods from one point to another.

These include all aspects related to transport such as packaging, loading and transporting, storing, transporting, unloading and warehousing inventory management, customer service. Distribution, returns, recycling are some of the options.

Logisticians ensure the product reaches its destination in the most efficient manner. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They can also track shipments in transit and monitor quality standards.

What is the responsibility of a logistics manager?

A logistics manager ensures that all goods are delivered on time and without damage. This is done by using his/her experience and knowledge of the company's products. He/she should also ensure enough stock is available to meet demand.

How can manufacturing efficiency be improved?

The first step is to determine the key factors that impact production time. We then need to figure out how to improve these variables. If you don't know where to start, then think about which factor(s) have the biggest impact on production time. Once you've identified them all, find solutions to each one.

How does a Production Planner differ from a Project Manager?

A production planner is more involved in the planning phase of the project than a project manger.

What does manufacturing industry mean?

Manufacturing Industries is a group of businesses that produce goods for sale. Consumers are the people who purchase these products. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. These companies produce goods using raw materials and other equipment. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

What is the importance of logistics in manufacturing?

Logistics is an integral part of every business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics also play a major role in reducing costs and increasing efficiency.

What is the difference in Production Planning and Scheduling, you ask?

Production Planning (PP), also known as forecasting and identifying production capacities, is the process that determines what product needs to be produced at any particular time. This can be done by forecasting demand and identifying production capabilities.

Scheduling refers the process by which tasks are assigned dates so that they can all be completed within the given timeframe.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was created in Japan by Taiichi Ohno during the 1970s and 80s. He received the Toyota Production System award (TPS), from Kanji Toyoda, founder of TPS. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

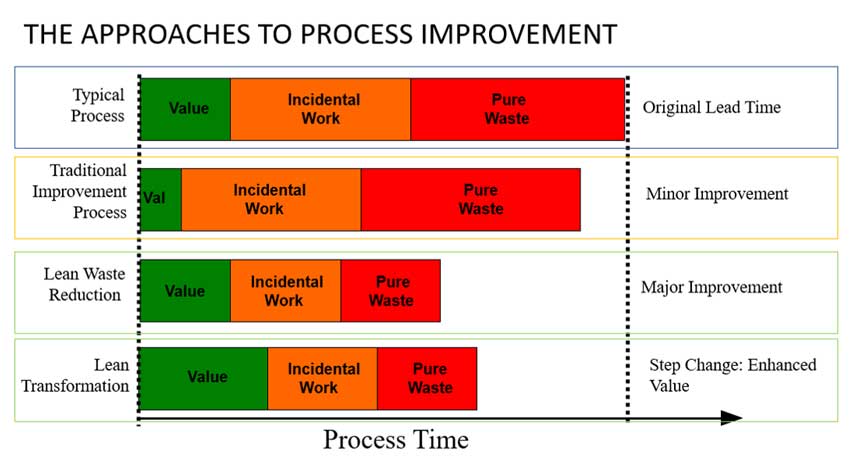

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It emphasizes reducing defects and eliminating waste throughout the value chain. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

In addition to improving product quality and reducing costs, lean manufacturing helps companies achieve their goals faster and reduces employee turnover. Lean manufacturing is considered one of the most effective ways to manage the entire value chain, including suppliers, customers, distributors, retailers, and employees. Lean manufacturing practices are widespread in many industries. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Five principles are the basis of lean manufacturing:

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many businesses have adopted lean manufacturing techniques to help them become more competitive. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing has many benefits in the automotive sector. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

Any aspect of an enterprise can benefit from Lean manufacturing. However, it is particularly useful when applied to the production side of an organization because it ensures that all steps in the value chain are efficient and effective.

There are three main types in lean manufacturing

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. You should repair any part that needs to be repaired during an assembly line. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous improvement involves continuous improvement of processes and people as well as tools.