Industrial engineers work in the field of manufacturing technology, and are skilled professionals who help to improve production processes. They develop new methods and analyze existing systems. Their expertise makes them highly valued in consulting, engineering services and research and development.

Although industrial engineers may work in many places, their primary focus is on improving the production process, reducing waste and internal costs. They use logic and creativity to create new production processes. Some industrial engineers focus on automated manufacturing processes.

Engineers need to have a solid understanding of mathematics and other scientific principles. They also need to be skilled at problem-solving, critical thinking, and other scientific principles. They should also be able to communicate well and work with others. Ideally, industrial engineers will be able to take a broad system's view and identify weaknesses and strengths of alternative solutions.

A bachelor's degree is required in order to pursue a career as an industrial engineer. You will also need at least four years experience. The Society of Manufacturing Engineers will allow you to become certified. You will be able to specialize by completing a master's in this field.

Industrial engineers are in high demand, and their job openings are expected to grow faster than the national average over the next ten years. The projected increase in employment for this profession is 10%. The majority of the work can be done on a full-time basis. Hours may vary depending on what the project calls for. The median salary for industrial engineers in Nashville is $73,856. The wage may vary depending on where you live, what employer you work for, and your individual qualifications.

When looking for an industrial engineering job in Nashville, it's important to highlight your educational and professional credentials. Additionally, it is important to obtain industry-specific certifications. You may require a professional engineer license if your goal is to work in a government agency.

Many companies hire interns in order to help them understand the intricacies behind industrial engineering. Interns will learn about lean manufacturing, value-stream mapping, and kaizen. Your skills and the company may allow you to progress your career to a managerial position.

Whether you're working in a lab or an office, you'll need to develop interpersonal communication skills to work effectively with colleagues and managers. Other than communicating with colleagues, you must also be able communicate with customers and suppliers.

A variety of industries are looking for skilled industrial engineers. These include transportation equipment manufacturers, computer and electronics manufacturers, and engineering service firms. Many colleges offer 5-year industrial engineering degrees. While many graduates are able to find entry-level positions in multiple industries, a few are more focused on certain specialty areas, such as automated manufacturing processes.

FAQ

What skills do production planners need?

Production planners must be flexible, organized, and able handle multiple tasks. Also, you must be able and willing to communicate with clients and coworkers.

What can I do to learn more about manufacturing?

The best way to learn about manufacturing is through hands-on experience. However, if that's not possible, you can always read books or watch educational videos.

What does it take for a logistics enterprise to succeed?

To be a successful businessman in logistics, you will need many skills and knowledge. For clients and suppliers to be successful, you need to have excellent communication skills. You should be able analyse data and draw inferences. You must be able to work well under pressure and handle stressful situations. You must be creative and innovative to develop new ideas to improve efficiency. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

It is important to be organized and efficient in order to meet tight deadlines.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

Six Sigma and Manufacturing

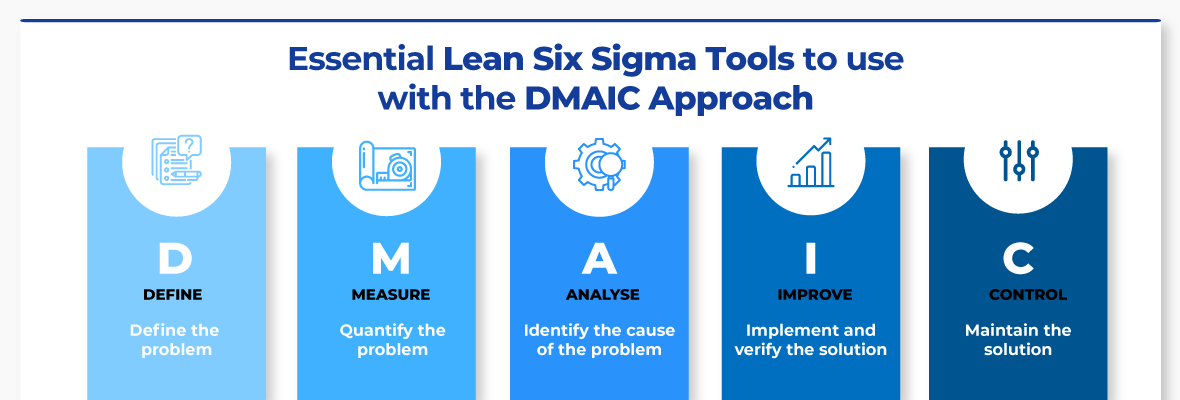

Six Sigma refers to "the application and control of statistical processes (SPC) techniques in order to achieve continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. Many companies have adopted this method in recent years. They believe there is no such thing a perfect product or service. Six Sigma's primary goal is to reduce variation from the average value of production. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

The first step toward implementing Six Sigma is understanding how variability works in your business. Once you've understood that, you'll want to identify sources of variation. You'll also want to determine whether these variations are random or systematic. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. You could consider random variations if some widgets fall off the assembly lines. It would be considered a systematic problem if every widget that you build falls apart at the same location each time.

Once you've identified where the problems lie, you'll want to design solutions to eliminate those problems. That solution might involve changing the way you do things or redesigning the process altogether. Once you have implemented the changes, it is important to test them again to ensure they work. If they don't work you need to rework them and come up a better plan.