Are you looking for New Jersey logistics jobs? These jobs come in all kinds of settings and require different skills, regardless of whether you are looking to become a manager or start your own business. But a bachelor's is recommended. You need these qualifications to become a logistics manager. These skills include the ability and willingness to work alone and solve problems. It is important to have a positive attitude, be a problem-solver and possess a positive mindset.

Bachelor's degrees are required

You will need to have a bachelor's degree from an accredited university and 4+ years of experience in logistics. Additionally, you must demonstrate organizational and time-management skills. In addition, you must possess strong communication skills and a solid command of the English language. Furthermore, you will need to be proficient in data analysis, have demonstrated leadership skills, and possess excellent interpersonal skills.

Many of these positions require a Bachelor's Degree in Logistics in New Jersey. This field is primarily middle-skilled but you can still make a lot of money if your skills are applied to different industries. New Jersey has many middle-skill jobs that need workers with specialized training. NJCU offers one of these programs at the Center for Workforce and Community Development.

Employers will often consider work experience in logistics over a college degree. You can be more marketable with prior experience and improve your chances of getting hired. You may have a job as a customer service representative or freight agent if you have a bachelor's degree in logistics. If you have the experience and qualifications, there are higher-level logistics positions available, such as management. Moreover, you can also pursue higher education in logistics, such as postsecondary teaching or research.

A bachelor's degree in engineering is preferred

Many logistics jobs require a bachelor’s degree. A bachelor’s degree in a related field, however, is preferred for many. Most employers prefer applicants with a bachelor's degree, because it enables them to handle complicated supply chains and transportation laws. A bachelor's degree gives students a broad knowledge of logistics and helps them to build professional networks. One entry-level job in logistics could be as a dispatcher or customer service representative. With advanced training and credentials, management positions may open up. There are other options available for high-level logistics positions, including research, consulting, and postsecondary education.

Most employers prefer a bachelor's in logistics. However, an associate's may be acceptable. Relevant work experience could be used in some cases to replace education. Certifications in industry-specific fields such as data analysis, warehouse management, or supply chain management are also helpful for job seekers. However, a bachelor's degree will still be preferred for logistics jobs in New Jersey. A bachelor's degree will equip you with the knowledge necessary to understand the inner workings and dynamics of a supply chain. Many companies require a bachelor's degree, particularly if they handle large-scale transactions.

A bachelor's degree and experience in manufacturing are required if you want to be an Industrial Engineer. Moreover, you must have knowledge of municipal coding rules and must be able to effectively communicate with employees. An Industrial Engineer must have at minimum six years of relevant experience, and be familiar working conditions in industries similar to yours.

FAQ

Is there anything we should know about Manufacturing Processes prior to learning about Logistics.

No. You don't have to know about manufacturing processes before learning about logistics. It is important to know about the manufacturing processes in order to understand how logistics works.

How can manufacturing avoid production bottlenecks

Production bottlenecks can be avoided by ensuring that processes are running smoothly during the entire production process, starting with the receipt of an order and ending when the product ships.

This includes planning for both capacity requirements and quality control measures.

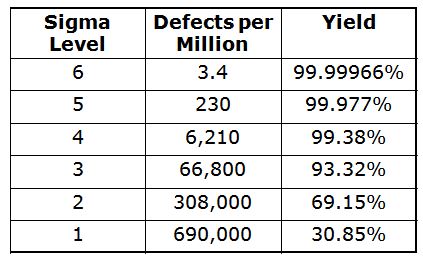

Continuous improvement techniques like Six Sigma are the best way to achieve this.

Six Sigma is a management system used to improve quality and reduce waste in every aspect of your organization.

It emphasizes consistency and eliminating variance in your work.

How can we improve manufacturing efficiency?

First, we need to identify which factors are most critical in affecting production times. The next step is to identify the most important factors that affect production time. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you identify them, look for solutions.

How can manufacturing excess production be decreased?

In order to reduce excess production, you need to develop better inventory management methods. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. This would allow us to use our resources for more productive tasks.

Kanban systems are one way to achieve this. A Kanban board, a visual display to show the progress of work, is called a Kanban board. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state represents an individual priority level.

To illustrate, work can move from one stage or another when it is complete enough for it to be moved to a new stage. It is possible to keep a task in the beginning stages until it gets to the end.

This helps to keep work moving forward while ensuring that no work is left behind. A Kanban board allows managers to monitor how much work is being completed at any given moment. This allows them the ability to adjust their workflow using real-time data.

Lean manufacturing is another option to control inventory levels. Lean manufacturing seeks to eliminate waste from every step of the production cycle. Any product that isn't adding value can be considered waste. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Materials in excess

These ideas can help manufacturers improve efficiency and reduce costs.

What can I do to learn more about manufacturing?

Practical experience is the best way of learning about manufacturing. However, if that's not possible, you can always read books or watch educational videos.

What are the four types in manufacturing?

Manufacturing is the process that transforms raw materials into useful products. It involves many different activities such as designing, building, testing, packaging, shipping, selling, servicing, etc.

What is the importance of logistics in manufacturing?

Logistics are an essential part of any business. They can help you achieve great success by helping you manage product flow from raw material to finished goods.

Logistics play an important role in reducing costs as well as increasing efficiency.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to Use the Just-In-Time Method in Production

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It is a process where you get the right amount of resources at the right moment when they are needed. This means that your only pay for the resources you actually use. Frederick Taylor developed the concept while working as foreman in early 1900s. He noticed that workers were often paid overtime when they had to work late. He decided to ensure workers have enough time to do their jobs before starting work to improve productivity.

The idea behind JIT is that you should plan ahead and have everything ready so you don't waste money. You should also look at the entire project from start to finish and make sure that you have sufficient resources available to deal with any problems that arise during the course of your project. You'll be prepared to handle any potential problems if you know in advance. This way, you won't end up paying extra money for things that weren't really necessary.

There are many JIT methods.

-

Demand-driven: This type of JIT allows you to order the parts/materials required for your project on a regular basis. This will let you track the amount of material left over after you've used it. This will let you know how long it will be to produce more.

-

Inventory-based : You can stock the materials you need in advance. This allows you to forecast how much you will sell.

-

Project-driven : This is a method where you make sure that enough money is set aside to pay the project's cost. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT: This type of JIT is most commonly used. You allocate resources based on the demand. For example, if there is a lot of work coming in, you will have more people assigned to them. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based : This is similar in concept to resource-based. But here, you aren't concerned about how many people your company has but how much each individual costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based JIT is another form of resource-based JIT. Instead of worrying about how much each worker costs, you can focus on how long the project takes.

-

Quality-based JIT is another variant of resource-based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based JIT: One of the most recent forms of JIT. You don't worry about whether the products work or if they meet customer expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based: This inventory-based approach focuses on how many items are being produced at any one time. It is used when production goals are met while inventory is kept to a minimum.

-

Just-in-time (JIT) planning: This is a combination of JIT and supply chain management. This refers to the scheduling of the delivery of components as soon after they are ordered. It's important because it reduces lead times and increases throughput.