Electric cars are vehicles which use batteries to store electricity and power their motors. These vehicles are more fuel-efficient and cleaner than gasoline powered cars, and they can be charged by electricity at public charging stations.

It is important to know the components of an electric car before driving one. Among them are the electric motor, the battery pack and the auxiliary batteries.

Batteries are designed to store energy. They're used in various applications, such as for lighting and horns. The battery connects to the motor. This in turn powers the wheels. The battery can also be connected to the auxiliary power source, which provides energy for the vehicle's equipment and accessories.

A controller regulates flow of electricity between the battery and the motor based on signals received from an accelerator pedal. The controller will also control the motor's speed in order to match the speed that the driver is pressing on the accelerator pedal.

Regenerative braking is a technique that uses the momentum of the vehicle to convert its kinetic energy into electrical power. This energy then goes back into the batteries, helping to recharge them.

A battery in an EV car is larger because it is meant to be efficient and fast. The battery will store energy until needed. The car can only accelerate once the battery has been fully charged.

The regenerative braking system helps the driver slow down faster than with a gas car, so it is ideal for "one-pedal driving." The electric motor also has a lower center of gravity than a traditional gas vehicle, which helps to improve the handling of an EV and reduces rollovers.

Inverters are specialized devices that convert high-voltage electrical power from the battery to low-voltage electricity to recharge the auxiliary batteries. This can be done at a public charging station or by attaching an external power source to the battery.

You can charge your EV in many ways, but the majority of people use a standard cable. You may also find a fast charger, which is connected to an external power source and can provide a higher-speed charge to the battery than a standard charging station.

EVs that use multiple motors can extend their range by allowing them to move faster. The number and type of motors depend on the vehicle's design, power requirements, and the vehicle's type.

GE Appliance Park

In Louisville, Kentucky's GE Appliance park, a new self-driving fleet of electric trucks is being developed. These trucks will transport goods throughout the United States. The company is working with a Swedish company to create driverless trucks.

General Electric Ceo

GE is not only a leading manufacturer of consumer products but also of engines and other machinery. CEO Mary Barra has made a point of investing in new technologies that will benefit GE's customers.

FAQ

What are the main products of logistics?

Logistics refers to all activities that involve moving goods from A to B.

They include all aspects associated with transport including packaging, loading transporting, unloading storage, warehousing inventory management customer service, distribution returns and recycling.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

Do we need to know about Manufacturing Processes before learning about Logistics?

No. No. But, being familiar with manufacturing processes will give you a better understanding about how logistics works.

How can manufacturing overproduction be reduced?

The key to reducing overproduction lies in developing better ways to manage inventory. This would reduce time spent on activities such as purchasing, stocking, and maintaining excess stock. By doing this, we could free up resources for other productive tasks.

You can do this by adopting a Kanban method. A Kanban board can be used to monitor work progress. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state is assigned a different priority.

As an example, if work is progressing from one stage of the process to another, then the current task is complete and can be transferred to the next. However, if a task is still at the beginning stages, it will remain so until it reaches the end of the process.

This allows work to move forward and ensures that no work is missed. Managers can monitor the work being done by Kanban boards to see what is happening at any given time. This information allows them to adjust their workflow based on real-time data.

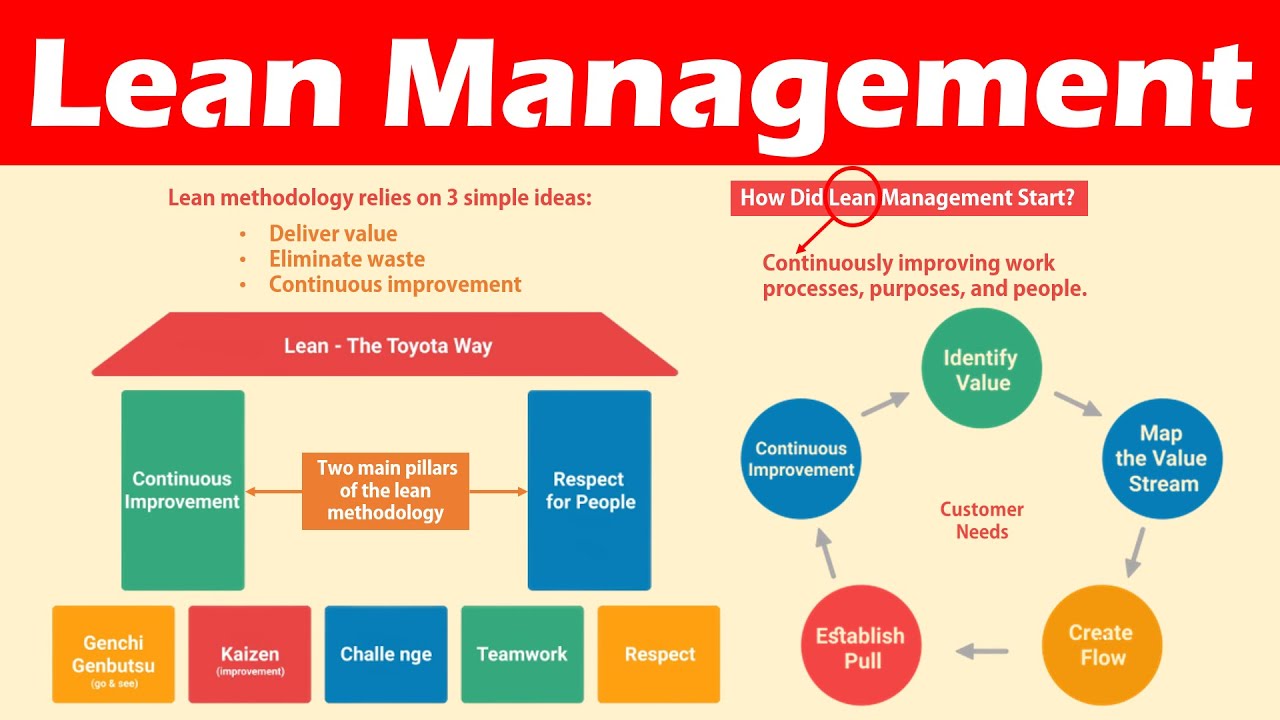

Lean manufacturing, another method to control inventory levels, is also an option. Lean manufacturing emphasizes eliminating waste in all phases of production. Anything that doesn't add value to the product is considered waste. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Exceed materials

These ideas can help manufacturers improve efficiency and reduce costs.

What are the 7 Rs of logistics.

The acronym 7R's of Logistic is an acronym that stands for seven fundamental principles of logistics management. It was developed by International Association of Business Logisticians (IABL), and published as part of their "Seven Principles of Logistics Management Series" in 2004.

The following letters form the acronym:

-

Responsible – ensure that all actions are legal and don't cause harm to anyone else.

-

Reliable - have confidence in the ability to deliver on commitments made.

-

Reasonable - make sure you use your resources well and don't waste them.

-

Realistic - Consider all aspects of operations, including environmental impact and cost effectiveness.

-

Respectful - show respect and treat others fairly and fairly

-

Reliable - Find ways to save money and increase your productivity.

-

Recognizable provides value-added products and services to customers

What does warehouse mean?

A warehouse, or storage facility, is where goods are stored prior to being sold. It can be indoors or out. In some cases it could be both indoors and outdoors.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to Use Just-In-Time Production

Just-in-time is a way to cut costs and increase efficiency in business processes. This is where you have the right resources at the right time. This means you only pay what you use. Frederick Taylor, a 1900s foreman, first coined the term. He noticed that workers were often paid overtime when they had to work late. He realized that workers should have enough time to complete their jobs before they begin work. This would help increase productivity.

The idea behind JIT is that you should plan ahead and have everything ready so you don't waste money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. You'll be prepared to handle any potential problems if you know in advance. This way, you won't end up paying extra money for things that weren't really necessary.

There are many JIT methods.

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will allow for you to track the material that you have left after using it. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows one to predict how much they will sell.

-

Project-driven : This is a method where you make sure that enough money is set aside to pay the project's cost. Once you have an idea of how much material you will need, you can purchase the necessary materials.

-

Resource-based JIT: This type of JIT is most commonly used. This is where you assign resources based upon demand. For example, if there is a lot of work coming in, you will have more people assigned to them. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This is the same as resource-based except that you don't care how many people there are but how much each one of them costs.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based JIT is another form of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of thinking about the cost of each employee or the time it takes to produce something, you focus on how good your product quality.

-

Value-based JIT is the newest form of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, you focus on the added value that you provide to your market.

-

Stock-based is an inventory-based system that measures the number of items produced at any given moment. It is used when production goals are met while inventory is kept to a minimum.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. It is the process of scheduling components' delivery as soon as they have been ordered. It's important because it reduces lead times and increases throughput.